Maschine zur Herstellung von Kartons

Boxmat XCUT ist eine wirtschaftliche und vielseitige Maschine für die Produktion von Wellpappenkartons in kleinen Serien mit einem hervorragenden Preis-Leistungs-Verhältnis

Features:

- NEW FEATURE 2023 Machine gets the functionality of cutting boards of to the appropriate length. Transversal cutting knife is mounted on rear of the machine to prevent board jamming

- Slotting, Cutting, Scoring, Creasing, Board Trimming IN ONE CYCLE

- All-in-one construction eliminates production errors common with multi-modular machines

- Less than 60 seconds changeover time

- Funkcja docinania formatki po szerokości i długości

- Main settings for box production done from ONE intuitive 12” touch screen panel

- Built-in 40 FEFCO styles + Free Style

- No need for extra tools or dies

- Semi automatic machine setup

- Eco-friendly low energy power supply

- Up to 600 boxes per hour

Up to 600 boxes per hour

Precise cutting of boards

Built-in 40 FEFCO styles

Boxmat XCUT, the successor to Boxmat 2, is the most recent model in the box making machine range. The machine has been given a completely new design reminiscent of the largest model in the assortment, Boxmat HD. The new model includes the same features as the previous one, but not exclusively, as the design has allowed us to introduce a significant innovation.

The machine has been designed for corrugated cardboard boxes production from short to medium runs. With less than 60 seconds setup time, the machine can make boxes of virtually any size and style: from regular small boxes to large wraps and pallet boxes.

Boxmat XCUT is suitable mainly for companies requiring in-house production of corrugated boxes and flexibility of quick and frequent box size/type change. Slitting, creasing, removing excess board and glue flaps are all done in one pass on one compact machine – without the need for additional modules. The machine makes boxes out of single or double wall corrugated cardboard.

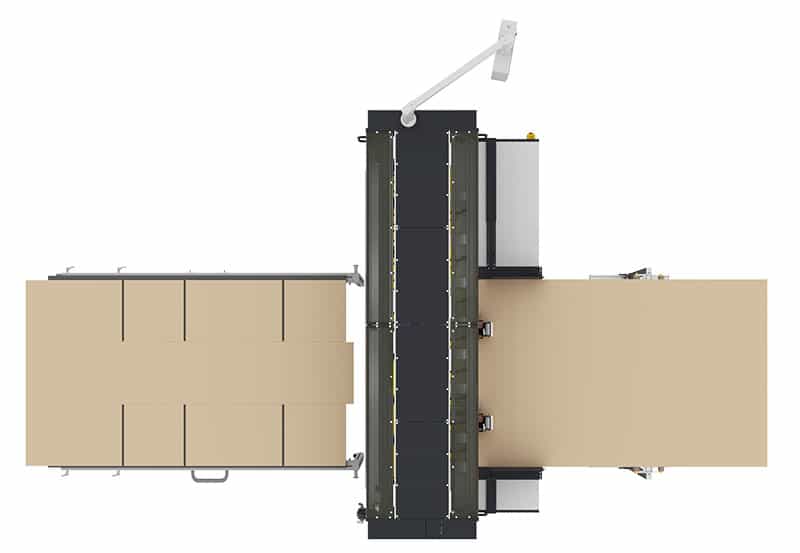

A new feature of the machine is its ability to cut the board to the desired length. The cross-cutting knife is installed at the machine’s exit and ensures collision-free excess board removal. This solution eliminates the need to pre-cut the board to the required length. Longitudinal and transverse trimming is now carried out in a single operation. This significantly improves the user’s comfort and the machine’s overall performance.

The use of Boxmat XCUT machines allows efficient manufacturing of a single box or hundreds, depending on the demand. With a maximum cardboard dimensions of 2500 mm x 10000 mm, the machine can produce large boxes with ease. All settings are entered directly from the 12” touch screen panel. The machine’s memory contains approximately 40 preprogrammed FEFCO box styles. The operator can easily produce boxes of any size based on the abovementioned FEFCO styles, or – thanks to Free Style mode – customise them to their individual requirements. The machine can store up to 1,000 recipes in its memory, which allows the user to easily return to previously made products. The dedicated unique software is very intuitive and easy to use.

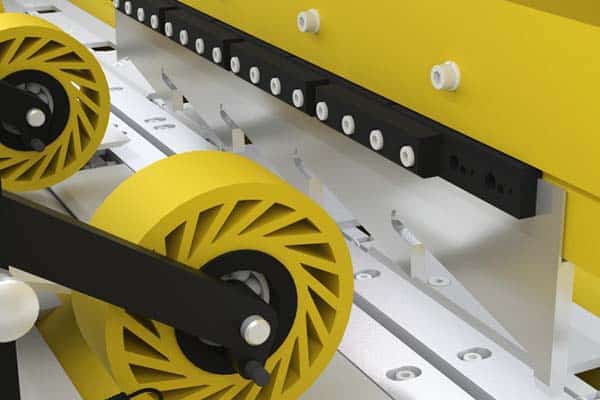

The blank sheet is positioned to the left edge with an automatically set bumper. This feature allows for the use of a razor blade knife for cutting off the cardboard excess and glue flap. Thanks to the new crosscut knife, board size adjustment is made without the need for precutting the blanks to the exact size (on a separate machine). Soft grip rolls and solid input/output shafts provide precision board feed control and prevent skewing. The use of a special anti-slip feeder assembly preventing cardboard skewing allows smooth and even feed through of small and large blanks. The slotting and creasing assembly has a special hardened steed feeding roll for increased precision and extended productivity. Special sectional knives are responsible for slitting. As standard, the machine has 10 knives, each 100 mm long, placed in sets of 5 both in the left and right section. The length of the sections can be adjusted by adding or removing the adequate number of knives (range 200 – 700 mm).

Sectional slotting knives

Sheet placed to the LEFT edge of the machine

Standard 12" HMI

- Many box styles available to make

- Ability to making custom boxes thanks to Free Style option

- Most settings done with electric drives

- Knife for trimming set manually

- Pressure for creasing/scoring wheels set manually with adjustment knob

- The blank sheet placed against the LEFT edge with automatically set bumper

- 10 sectional slotting knives (100 mm each)

- Two creasing rolls and three longitudinal formatting knives

- Board feeder with soft grip rolls

- External length control of the board

- Cutting off grue flap

- Precise boards trimming

- Built in secure VPN connection for HMI allowing remote diagnostics and update

- Vibration absorbing support feet

- Cooperate work with FLEXOMAT full-size flexographic printer

Boxmat Boxmakers are modern machines providing such capabilities and ease of use while maintaining competitive and good price. Furthermore they allow to lower the logistics costs since there is no need to order large quantities of one size boxes to have low cost.

BOXMAT XCUT -The Perfect Boxmaking Machine!

Technical Specification

Cardboard used: | Single or double wall B, C, EB, BC |

Types of boxes: | Preinstalled ~40 FEFCO styles + Frees Style |

Power supply: | 3 x 380/415/480 V (USA: 3 x 480 V / 20 A) |

Minimum board size: | 250 mm (10″) width x 550 mm (21″) |

Maximum board size: | 2500 mm (98″) width x 9999 mm (394”) length |

Odległość między nożami slotującymi: | 60-1500 mm (2 3/8”-59”) z nożami 500 mm |

Slot width: | 7-8 mm (~5/16″) |

Sectional slotting knives: | 100 mm (4”) each section |

Standard slotting knives length: | 500 mm (20”) each side |

Min/max slotting knives length | 200-700 mm (8-27½”) |

Footprint (L x W x H): | ~3300 x 1400 x 1550 mm (130 x 55 x 61”) |