All-in-one automatic shortrun boxes production system. INTELIGO as standard

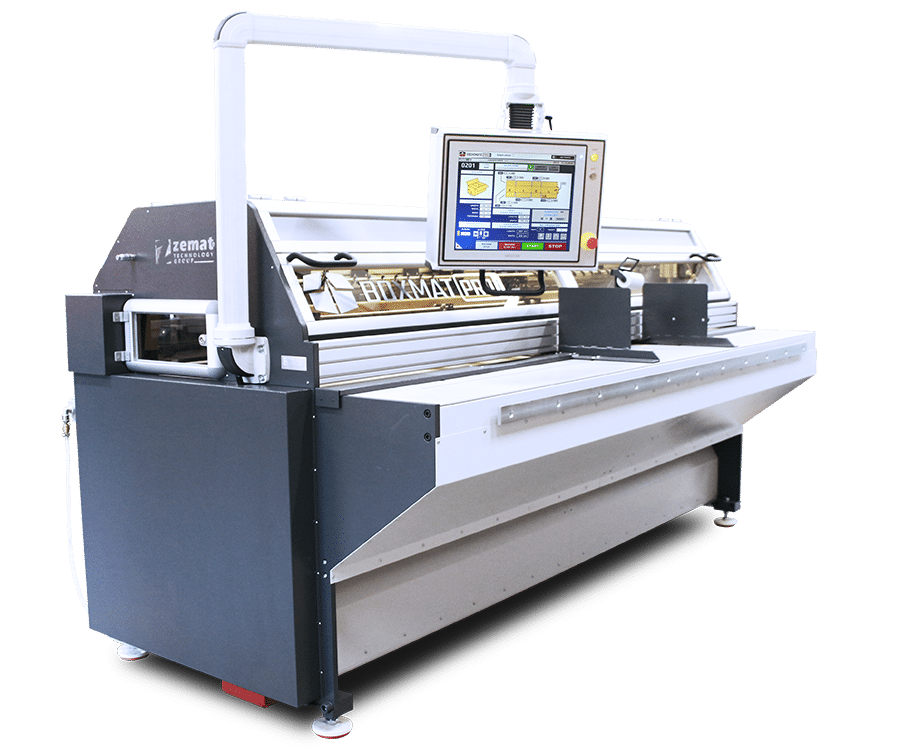

Boxmat PROi is an advanced cardboard box making machine revolutionizing the short and medium run serial production process of corrugated cardboard boxes. It features 19" touch screen HMI with Inteligo System

- 50 preprogrammed FEFCO box styles

- Under 60 sec. set-up time

- Low power consumption

- Eco-drive servo motion

- 10 sectional slotting knives

- 4 cutting knives (max. 8) - 2 types

- 4 scoring/creasing wheels (max. 8)

- External control of dimensions

- Secure VPN remote diagnostics

- No need for special tooling or dies

IN ONE MACHINE with all options installed!

- Slotting

- Board Trimming

- Scoring/Creasing

- Die Cutting

- Printing

- Gluing

All settings are entered directly from a touch screen panel with no manual tool adjustment. In less than 1 minute the machine can be reprogrammed for any of the 100 box styles. Slitting, scoring/creasing, gluing and printing is all done in one pass on one compact machine – without the need for additional equipment!

10 sectional slotting knives, 4 longitudinal cutting knives plus 4 scoring wheels are set automatically by the servo-drives to suit the size and thickness of the board. The cardboard is centrally positioned with auto-guides. Soft grip rollers and solid input/output shafts and double encoders provide precision board feed control and prevent skewing.

The innovative system of rotary knives installed in the rear cutting/scoring section allows for bi-directional board size adjustment without the need for precutting the blanks to the exact size on a separate machine.

The optional gluing section provides on-the-go single or double line cold glue application.

Short run box maker - check Out the video!

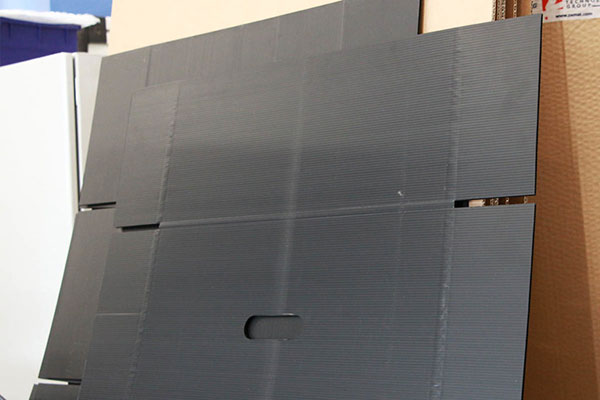

Box Samples

Inteligo System

19" touch screen panel with unique intuitive graphical user friendly interface with new options and capabilities.

- ALL settings on ONE large touch screen

- All values and settings visible in ONE place

- Great tool for beginners and inexperienced operators

- Built in Box Design WIZARD

- Easy correction of Scoring/Creasing and Cutting allowances

- Save box designs and recall from memory for production

- JQS Job Queue System - smart scheduling of boxes production flow process

Making perfect box after scanning in 3D the product to be packed

No LONG TERM corrugated board contracts!

With Boxmat machines, you have a freedom to choose your own corrugated supplier and make your own BOXES ON DEMAND

Sheets or Fanfold

The Boxmat series machines are truly universal systems which allow the use of single and double wall corrugated sheets as well as various widths of FANFOLD (Z-Fold) corrugated board.

Boxmat PROi Features

Adjustable double creasing rolls

Circular or blade knives

Slotting knives

BOXMAT machines can use Coroplast to make Corrugated Plastic Boxes

Standard stacker

Cardboard feeder

Optional output table:

- Detachable ready made

box receiving table

- Locking casters

- Expandable length

- Foldable for easy storage

Optional Features

Gluing System

miniFLEXO System

Automatic Stacker

BOXMAT PRO INTELIGO - The Perfect Cardboard Box Making Machine!

Technical Specification

Cardboard used: | Single and double wall (triple wall with limitations) |

Types of boxes: | Preinstalled 50 FEFCO styles + free style |

Power supply: | 3 x 380/415/480 V (USA: 3 x 480 V / 20 A) |

Minimum board size: | 250 mm (10”) width x 650 mm (25”) length |

Maximum board size: | 2400 mm (94”) width x 10000 mm (394″) |

Min./max. distance between slots: | 70 — 2000 mm (2¾ — 79”) |

Slot width: | 8 mm (5/16”) |

Sectional slotting knives: | 100 mm (4”) each |

Standard slotting knives length: | 500 mm (20”) each side |

Min./max. slotting knives length: | 200 — 700 mm (8 — 27 1/2”) |

Glue flap: | from 5 mm (3/16”) |

Footprint (L x W x H): | 3300 x 1600 x 1600 mm (130 x 63 x 63”) |