Trabaja con Hojas Corrugado Regulares o de Alto Calibre o Fanfold

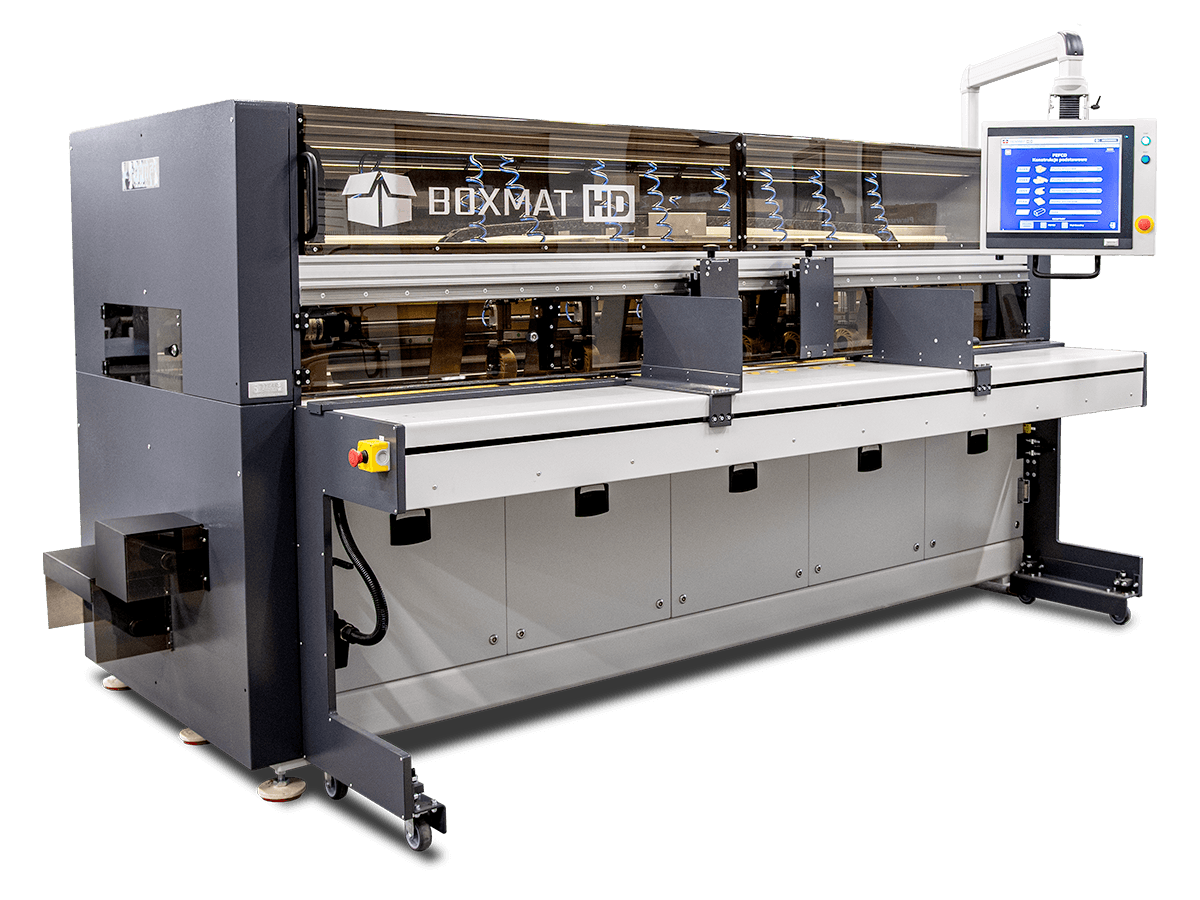

The most versatile of BOXMAT series model with High Density (Heavy Duty) corrugated board capabilities, built-in Die Cutting and Gluing option

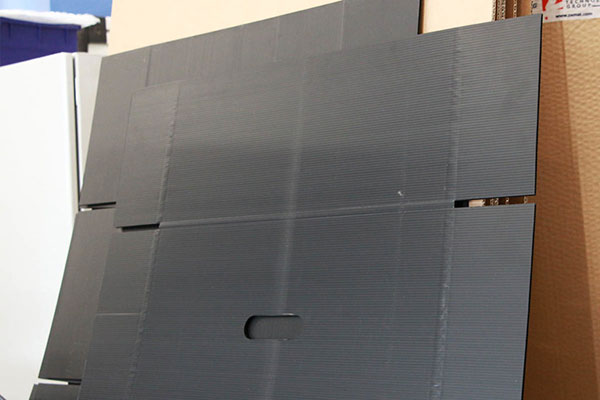

Sample Boxes

SLITTING

SLOTTING

CUTTING

TRIMMING

CREASING

SCORING

DIE CUTTING

PRINTING

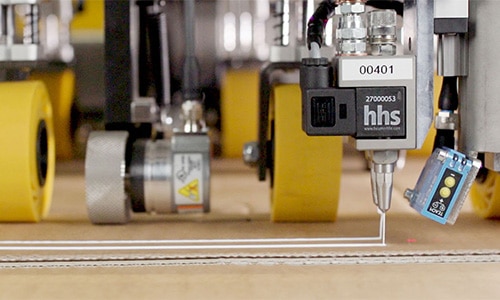

GLUING

In ONE compact machine!

SLITTING

SLOTTING

CUTTING

TRIMMING

CREASING

SCORING

DIE CUTTING

PRINTING

GLUING

Features:

- One pass operation to make a perfect box

- Single, Double wall and Heavy Duty board

- Sheets and Fanfold use

- Die Cutting built-in

- Switchover time – less than 30 seconds

- Fully automatic servo-drive setup

- Counter-knife and counter scoring/creasing system

- Large 19” touch screen HMI

Integrated Inteligo System:

- JQS Job Queue System production scheduling

- Box Design WIZARD

- MRP/ERP manufacturing integration

- Barcode reader

- Optional 3D product scanning

Sheets or Fanfold

No LONG TERM corrugated board contracts!

With Boxmat machines, you have a freedom to choose your own corrugated supplier and make your own BOXES ON DEMAND

Boxmat HD Features

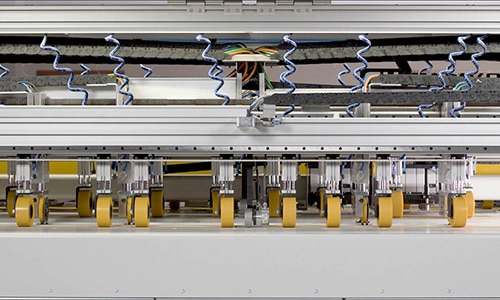

Detachable precision cardboard feeder. The machine can be fully configurable to be used with manual feed, printer or fully automatic feed

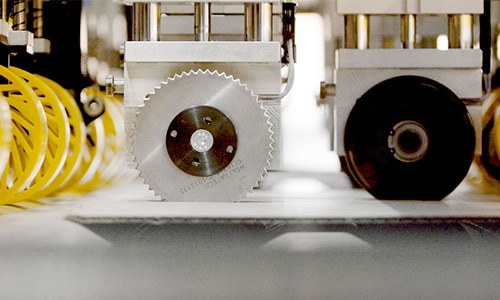

The die cutting system with extra built-in beam equipped with two die-cutting units and work area of 210x130 mm (8.25x5.1”) each, with independent drives to set in the right position. It enables cutting out handles, revisions or angular cuts in corrugated box panels

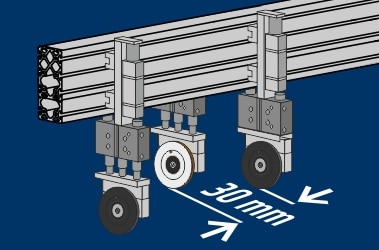

Independent drive for each tool nest provides very fast position setup

Minimum distance between tools: 30 mm

BOXMAT machines can use Coroplast to make Corrugated Plastic Boxes

Adjustable double creasing rolls

Circular or blade knives

Slotting knives

Optional output table:

- Detachable ready made

box receiving table

- Locking casters

- Expandable length

- Foldable for easy storage

- Fully programmable interface for box creation in any style and size

- Detachable precision cardboard feeder. The machine can be fully configurable to be used with manual feed, printer or fully automatic feed

- The new design of beams provides much less wear of the slotting knives

- Double die cutting system with independent drives and die cutting units 210 x 130 mm (8.25 x 5.1”) each. It enables cutting out handles, revisions or angular cuts in corrugated box panels

- Upgraded design of slotting knives drive provides much less wear

- Reinforced chassis construction assures less vibrations during production process

- Additional shaft for feeding the corrugated board

- Independent drive for each tool nest provides very fast position setup

- Each tool nest can handle either scoring/creasing wheels or knives

- Minimum distance between tools: 30 mm (3/16”)

- Automatic recognition of the specific tool in the nest

- Synchronized counter-crease and counter-knife system

- Intuitive software with APC capabilities and remote control

- Ability to set the tools in-line, one-after-another e.g. for double creasing of heavy boards

- Built-in VPN secure connection for HMI allowing remote calibration and updates

Fast servo-drive setup of ALL TOOLS

Conveyor waste/scrap REMOVAL system

Integrated DIE CUTTING, precision Cut-and-Score

COUNTER-CREASE and COUNTER-KNIFE system

BOXMAT HD - ¡La Máquina Perfecta Para Fabricar Cajas Corrugadas!

Especificaciones Especificaciones

Corrugado a utilizar: | Sencillo y doble corrugado |

Modos de trabajo: | 45 estilos FEFCO instalados más asistente para diseño de cajas |

Potencia Eléctrica: | 3 x 380/415/480 V (USA: 3 x 480 V / 20 A) |

Tamaño máximo de hoja: | 2400mm (94”) ancho x 10000 mm (394”) largo |

Tamaño mínimo de hoja: | 250mm (8”) ancho x 750mm (25”) |

Distancia entre cuchillas de ranurado: | 75-2100 mm (2¾-79″) con cuchillas de 200mm |

Ancho de ranura: | 8 mm (5/16″) |

Secciones de cuchillas de ranurado: | 100mm (4”) cada una |

Largo standard de cuchillas de ranurado: | 500mm (20”) cada lado |

Largo Min/Max de cuchillas de ranurado: | 200 – 700 mm (8 – 27½») |

Pestaña de pegado: | Desde 5 mm |

Dimensiones (L x W x H): | 3600 x 1900 x 1750 mm (142 x 75 x 69″) |

Peso: | 3800 kg |