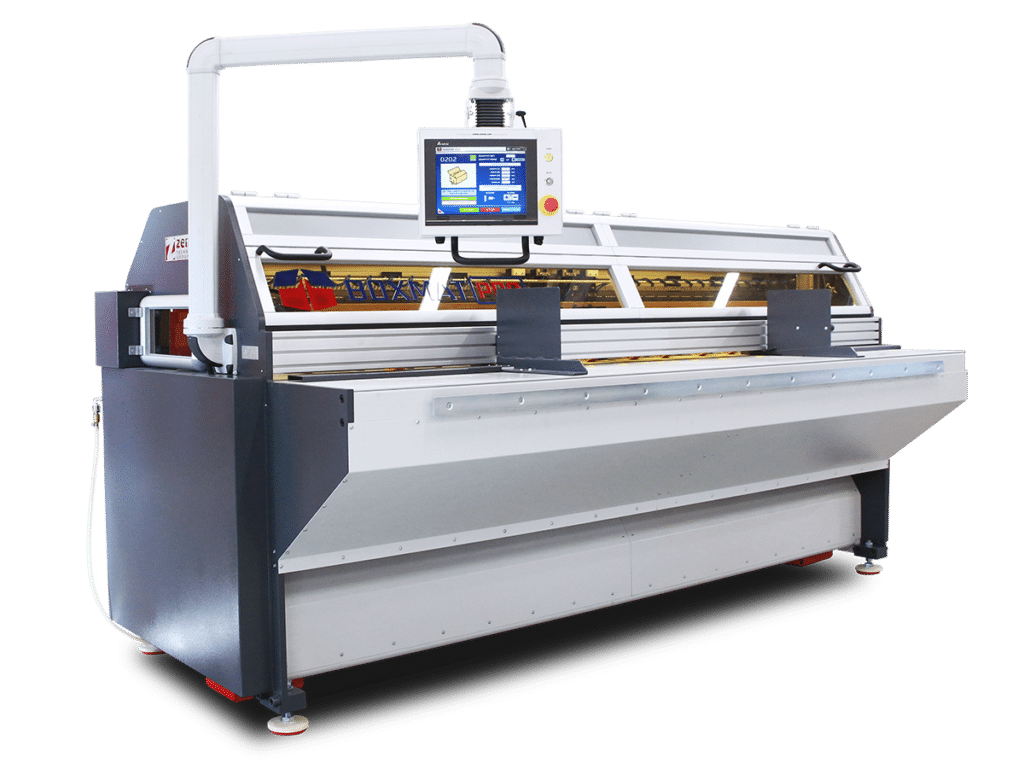

Automatic all-in-one cardboard box making machine

The most versatile box making machines revolutionizing the short and medium runs serial production of corrugated cardboard boxes.

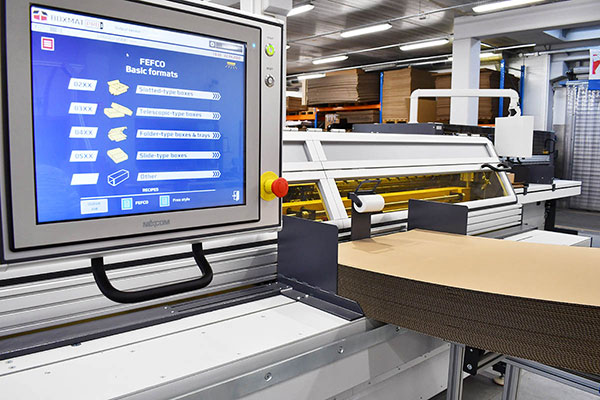

- Over 50 preprogrammed FEFCO box styles

- Under 60 sec. set-up time

- Low power consumption

- Eco-drive servo motion

- 10 sectional slotting knives

- 4 cutting knives (max. 8) - 2 types

- 4 scoring/creasing wheels (max. 8)

- External control of dimensions

- Secure VPN remote diagnostics

- No need for special tooling or dies

IN ONE MACHINE with all options installed!

- Slotting

- Board Trimming

- Scoring/Creasing

- Die Cutting

- Printing

- Gluing

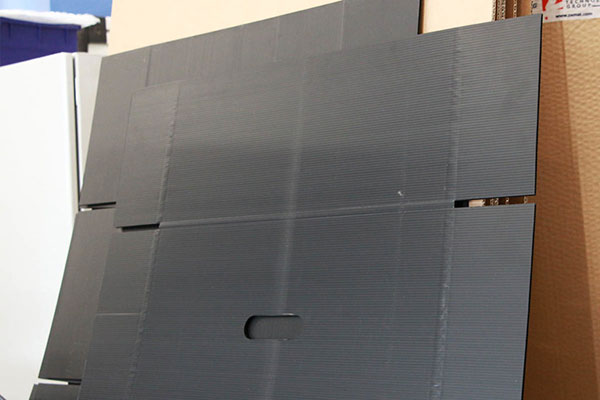

Box Samples

All settings are entered directly from a touch screen panel with no manual tool adjustment. In less than 1 minute the machine can be reprogrammed for any of the 100 box styles. Slitting, scoring/creasing, gluing and printing is all done in one pass on one compact machine – without the need for additional equipment!

10 sectional slotting knives, 4 longitudinal cutting knives plus 4 scoring wheels are set automatically by the servo-drives to suit the size and thickness of the board. The cardboard is centrally positioned with auto-guides. Soft grip rollers and solid input/output shafts and double encoders provide precision board feed control and prevent skewing.

The innovative system of rotary knives installed in the rear cutting/scoring section allows for bi-directional board size adjustment without the need for precutting the blanks to the exact size on a separate machine.

The optional gluing section provides on-the-go single or double line cold glue application.

No LONG TERM corrugated board contracts!

With Boxmat machines, you have a freedom to choose your own corrugated supplier and make your own BOXES ON DEMAND

Sheets or Fanfold

The Boxmat series machines are truly universal systems which allow the use of single and double wall corrugated sheets as well as various widths of FANFOLD (Z-Fold) corrugated board.

Boxmat PRO Features

- All settings for box production done from an intuitive touch screen panel

- Slotting, bi-directional scoring/creasing, cutting, gluing and printing in ONE CYCLE

- Automatic board feeder with soft grip rolls and optional receiving stacker

- Create your own design of boxes with FreeStyle settings

- Ability to modify standard FEFCO/RSC/OPF/FPF and other boxes

- No need for extra tools or dies / all settings done with servo drives

- Optional use of perforation knives and special shape scoring wheels

- Modular built for cutting knives (circular or blade) and scoring/creasing wheels

- Synchronized in-cycle glue application

- Printing and gluing can be added as optional features.

- Synchronous work with Flexomat full-size flexographic printer

Adjustable double creasing rolls

Circular or blade knives

Slotting knives

BOXMAT machines can use Coroplast to make Corrugated Plastic Boxes

Standard stacker

Cardboard feeder

Optional output table:

- Detachable ready made

box receiving table

- Locking casters

- Expandable length

- Foldable for easy storage

Optional Features

Gluing System

Innovative cold gluing system for boxmakers gives a fresh and exceptional approach to the corrugated cardboard gluing cycle!

miniFLEXO System

Additional printing system for Boxmat machines. One color mini-flexo technology printing.

Automatic Stacker

Automatic stacking of corrugated cardboard boxes made with Boxmat Boxmakers. Up to 2400 mm width of receiving boards.

BOXMAT PRO - ¡La Máquina Perfecta Para Fabricar Cajas Corrugadas!

Especificaciones Técnicas

Corrugado a utilizar: | sencillo y doble corrugado (triple corrugado c/restricciones) |

Tipos de cajas: | 45 estilos FEFCO instalados más estilo libre |

Potencia Eléctrica | 3 x 380/415/480 V (USA: 3 x 480 V/20 A) |

Tamaño máximo de hoja | 2400 mm (94”) ancho x 10000 mm largo |

Tamaño mínimo de hoja: | 200mm (8”) ancho x 650mm (25”) largo |

Distancia Min/Max entre cuchillas de ranurado: | 70 mm (2¾”) / 2000 mm (79”) |

Ancho de ranura: | 8 mm (5/16”) |

Secciones de cuchillas de ranurado: | 100 mm (4”) cada una |

Largo estándar de cuchillas de ranurado: | 500 mm (20”) cada lado |

Largo Min/Max de cuchillas de ranurado: | 200-700 mm (8-27 1/2”) |

Dimensiones (L x W x H): | 3300 x 1600 x 1600 mm (130 x 63 x 63”) |