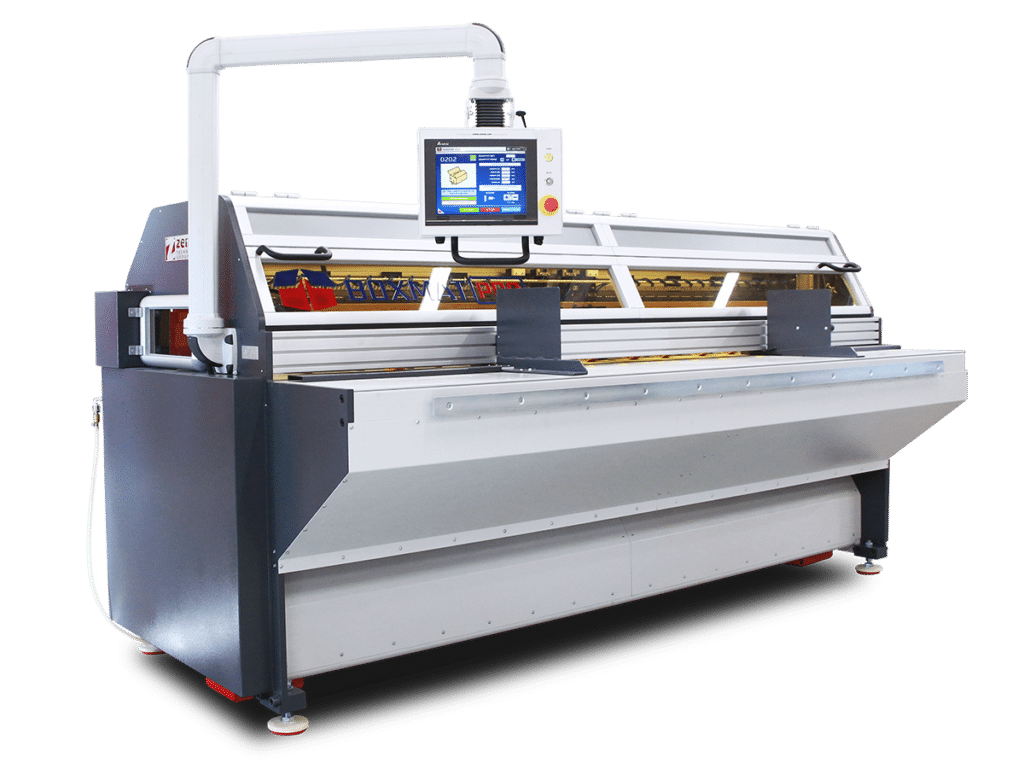

Automatic all-in-one cardboard box making machine

The most versatile box making machines revolutionizing the short and medium runs serial production of corrugated cardboard boxes.

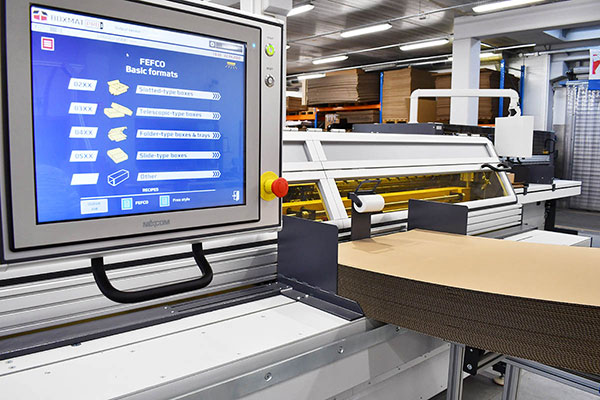

- Over 50 preprogrammed FEFCO box styles

- Under 60 sec. set-up time

- Low power consumption

- Eco-drive servo motion

- 10 sectional slotting knives

- 4 cutting knives (max. 8) - 2 types

- 4 scoring/creasing wheels (max. 8)

- External control of dimensions

- Secure VPN remote diagnostics

- No need for special tooling or dies

IN ONE MACHINE with all options installed!

- Slotting

- Board Trimming

- Scoring/Creasing

- Die Cutting

- Printing

- Gluing

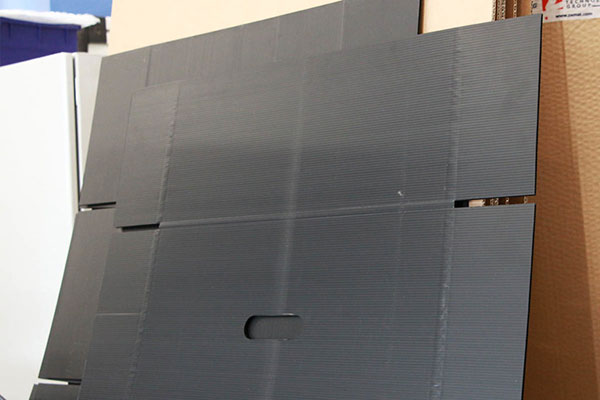

Box Samples

All settings are entered directly from a touch screen panel with no manual tool adjustment. In less than 1 minute the machine can be reprogrammed for any of the 100 box styles. Slitting, scoring/creasing, gluing and printing is all done in one pass on one compact machine — without the need for additional equipment!

10 sectional slotting knives, 4 longitudinal cutting knives plus 4 scoring wheels are set automatically by the servo-drives to suit the size and thickness of the board. The cardboard is centrally positioned with auto-guides. Soft grip rollers and solid input/output shafts and double encoders provide precision board feed control and prevent skewing.

The innovative system of rotary knives installed in the rear cutting/scoring section allows for bi-directional board size adjustment without the need for precutting the blanks to the exact size on a separate machine.

The optional gluing section provides on-the-go single or double line cold glue application.

No LONG TERM corrugated board contracts!

With Boxmat machines, you have a freedom to choose your own corrugated supplier and make your own BOXES ON DEMAND

Листовой картон или Z-картон

The Boxmat series machines are truly universal systems which allow the use of single and double wall corrugated sheets as well as various widths of FANFOLD (Z-Fold) corrugated board.

Boxmat PRO Features

- All settings for box production done from an intuitive touch screen panel

- Slotting, bi-directional scoring/creasing, cutting, gluing and printing in ONE CYCLE

- Automatic board feeder with soft grip rolls and optional receiving stacker

- Create your own design of boxes with FreeStyle settings

- Ability to modify standard FEFCO/RSC/OPF/FPF and other boxes

- No need for extra tools or dies / all settings done with servo drives

- Optional use of perforation knives and special shape scoring wheels

- Modular built for cutting knives (circular or blade) and scoring/creasing wheels

- Synchronized in-cycle glue application

- Printing and gluing can be added as optional features.

- Synchronous work with Flexomat full-size flexographic printer

Adjustable double creasing rolls

Circular or blade knives

Slotting knives

BOXMAT machines can use Coroplast to make Corrugated Plastic Boxes

Standard stacker

Cardboard feeder

Optional output table:

- Detachable ready made

box receiving table

- Locking casters

- Expandable length

- Foldable for easy storage

Optional Features

Gluing System

miniFLEXO System

Automatic Stacker

BOXMAT PRO - идеальное решение для производства гофрокоробов!

Техническая Cпецификация

Обрабатываемые материалы: | 3- и 5-слойный гофрокартон. |

Стили коробок: | 50 установленных стилей FEFCO + Конфигуратор коробок |

Электропитание: | 3 x 380/415/480 V |

Максимальный размер листа: | ширина 2400 мм, длина 10000 мм |

Минимальный размер листа: | ширина 250 мм x длина 650 мм |

Мин/Макс. расстояние между ножами для пазов: | 70/2000 мм |

Ширина паза: | 8 мм) |

Ножи для пазов: | сегменты по 100 мм |

Стандартная длина ножей для пазов: | по 500 мм каждый (левый и правый) |

Мин/Макс. длина ножей для пазов: | 200 — 700 мм |

Габариты (Д x Ш x В): | 3300 x 1600 x 1600 мм |