Wszechstronna maszyna do produkcji opakowań kartonowych

Zaprojektowana z myślą o dużej gramaturze,

tekturze falistej i wstędze

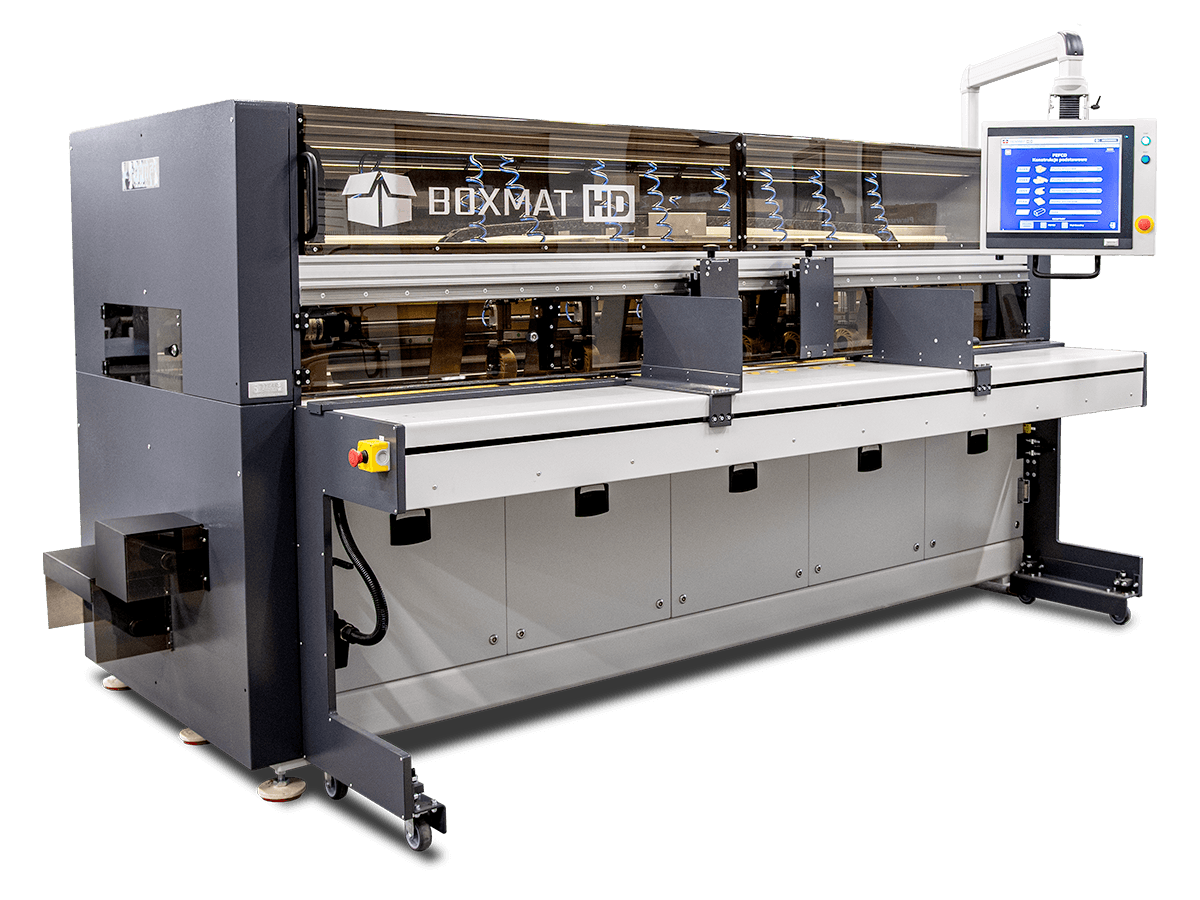

Boxmat HD to najbardziej zaawansowana i wszechstronna maszyna do produkcji opakowań kartonowych w naszej ofercie.

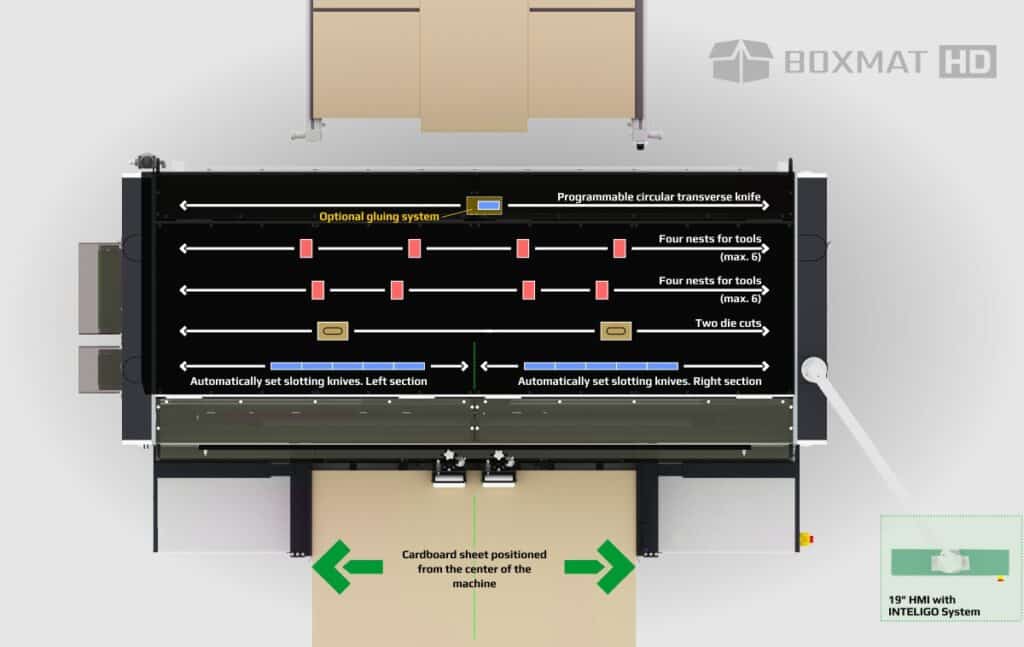

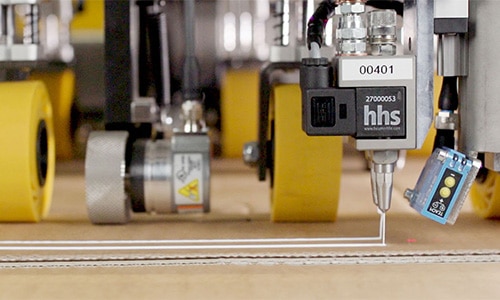

Wyposażona w zintegrowany moduł sztancujący oraz opcję nanoszenia kleju, zapewnia pełną elastyczność produkcji. Może pracować zarówno w trybie ręcznego podawania arkuszy, jak i z automatycznymi podajnikami – w zależności od potrzeb Twojej linii produkcyjnej.

BOXMAT HD - Wszechstronna maszyna do produkcji opakowań kartonowych

Nowości:

- Nowa konstrukcja narzędzi wzdłużnych - zmniejszona minimalna odległość między nimi

- Możliwość użycia podwójnych rolek bigujących

- Ulepszona identyfikacja narzędzi - system automatycznego wykrywania typu narzędzia na belce

Właściwości:

- 40+ zainstalowanych stylów FEFCO, 100+ możliwych rodzajów opakowań

- Tylko jeden przejazd kartonu do uzyskania idealnego pudełka

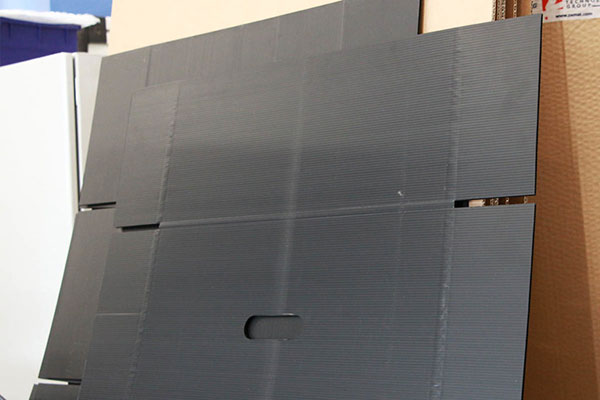

- Cięcie trzy- i pięciowarstwowej tektury o wysokiej gęstości

- Możliwość użycia arkuszy lub kartonu ze wstęgi

- Zintegrowany system do wycinania rączek

- Automatyczne przezbrojenie w czasie poniżej 30 sek.

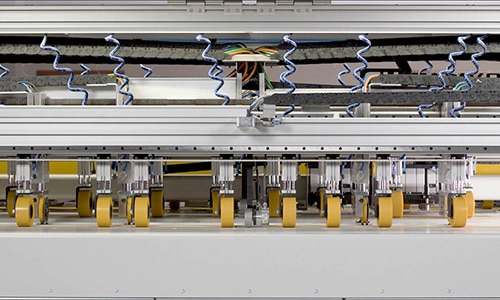

- Niezależne ustawianie narzędzi przy pomocy serwonapędów

- System kontrnoży i kontrbigów

- Duży 19” ekran dotykowy

Integrated Inteligo System:

- System kolejkowania zadań

- Graficzny kreator pudełek

- Możliwość integracji z systemami ERP

- Czytnik kodów kreskowych

- Opcjonalne skanowanie produktów do zapakowania w 3D

Pełna niezależność w produkcji opakowań kartonowych!

Maszyna do produkcji opakowań kartonowych

BOXMAT HD - Właściwości:

- W pełni programowalny interfejs do tworzenia pudełek w dowolnym stylu i rozmiarze

- Odłączany podajnik kartonu. Możliwość konfiguracji maszyny w sposób aktualnie odpowiadający potrzebom, a w przyszłości możliwość wymiany na inny (np. ze standardowego ręcznego na automatyczny)

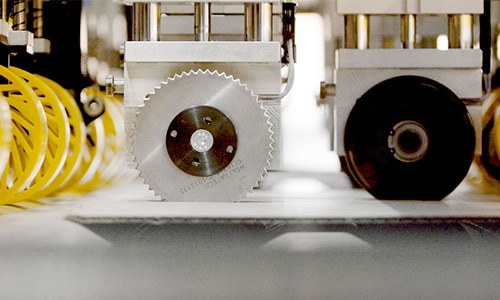

- Nowa konstrukcja belek zapewnia znacznie mniejsze zużycie noży do slotów

- Maszyna do produkcji opakowań kartonowych, która może pracować zarówno z arkuszami, jak i tekturą ze wstęgi.

- Dwa zespoły sztancujące i obszar roboczy o wymiarach 210x130 mm każdy, z niezależnymi napędami do ustawiania we właściwej pozycji.

- Wzmocniona konstrukcja nośna zapewnia minimalizuje wibracje podczas procesu produkcyjnego

- Dodatkowy wał do podawania tektury

- Niezależny napęd każdego narzędzia minimalizujący czas ustawiania

- Możliwość założenia dowolnego narzędzia - bigu lub noża - w każdym z gniazd

- Minimalna odległość między narzędziami: 30 mm (3/16”)

- Belka wyposażona w system kontrbigowania i kontrnoże

- Możliwość ustawienia narzędzi w jednej linii (jedno za drugim), w celu np. podwójnego bigowania ciężkich arkuszy

- Wbudowany VPN dający możliwość zdalnej kalibracji lub aktualizacji

Arkusze lub wstęga:

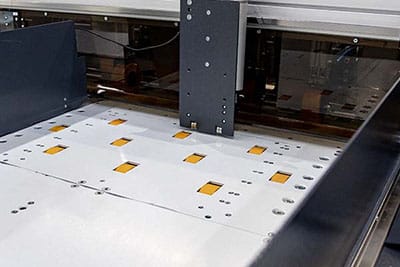

- System sztancujący:

- System sztancowania na dodatkowej wbudowanej belce. Dwa zespoły sztancujące i obszar roboczy o wymiarach 210x130 mm każdy, z niezależnymi napędami do ustawiania we właściwej pozycji. Umożliwia wycinanie uchwytów, rewizji lub nacięć kątowych w panelach z tektury falistej.

- Opcjonalny stół odbiorczy:

- Samodzielna komnstrukcja

- Blokowane kółka

- Regulowana długość

- Składana konstrukcja, łatwe przechowywanie

Przykładowe pudełka:

Właściwości i zalety:

- Niezależny napęd dla każdego gniazda narzędziowego zapewnia bardzo szybkie ustawienie pozycji

- Podajnik podciśnieniowy

- Możliwość użycia materiału Coroplast do produkcji pudeł z tworzywa!

- Regulowane podwójne rolki bugujące

- Krążkowe lub żyletkowe noże

- Noże slotujące

- Intuicyjny interfejs HMI z wbudowanym kreatorem pudełek

- Szybkie ustawianie narzędzi za pomocą indywidualnych serwonapędów

- Taśmowy system usuwania odpadów/ścinków kartonu

- Zintegrowany system wykrojników do wycinania rączek

- System kontrbigów i kontrnoży

PODAJNIK NOŻYCOWY LWF

- Podajnik zapewnia automatyczne pobieranie formatek z podstawionego na palecie stosu.

- Formatki pobierane są za pomocą pneumatycznych ssawek.

- Wysokość stosu kartonów jest automatycznie dostosowywana do wysokości pobierania za pomoca podnośnika nożycowego.

- Odległości między ssawkami ustawiane są ręcznie w zależności od szerokości stosu.

- Podajnik LWF łatwo integruje się z maszynami typu Boxmat, co zapewnia maksymalną synchronizację oraz bezkolizyjne wprowadzanie formatek.

- Maks. obsługiwana wysokość stosu 900 mm (z paletą).

- Maksymalny wymiar arkusza: 1500 mm szerokość x 2500 mm długość

- Minimalny wymiar arkusza: Zależna od podłączonego modelu boxmata

Specyfikacja techniczna:

Obsługiwane materiały: | Tektura 3-warstwowa, tektura 5-warstwowa. Fala: B, C, EB, BC |

Style pudełek: | ~40 preinstalowanych stylów FEFCO + Kreator Pudełek |

Zasilanie: | 3 x 380/415/480 V |

Minimalny wymiar arkusza: : | 250 mm szerokość x 750 mm |

Maksymalny wymiar arkusza: | 2400 mm szerokość x 9999 mm

długość |

Odległość między nożami slotujacymi: | 75 – 2000 mm (z nożami o długości 200 mm) |

Szerokość slotów: | 7 – 8 mm |

Noże slotujące: | segmenty po 100 mm każdy |

Standardowa długość noży slotujących: | po 500 mm (lewy i prawy) |

Długość noży slotujących: | 200 – 700 mm |

Zakładka klejowa: | od 5 mm |

Wymiary (Dł. x Szer. x Wys.): | 3600 x 1900 x 1750 mm |

Waga: | 3800 kg |

Maszyna do produkcji opakowań kartonowych

– doradztwo, konfiguracja, serwis

Model Boxmat HD to najbardziej zaawansowana i wszechstronna maszyna do produkcji opakowań kartonowych, która doskonale sprawdza się w zakładach oczekujących wysokiej automatyzacji i pracy z tekturą falistą o dużej gramaturze. Dzięki szerokiemu wachlarzowi funkcji – od sztancowania po nanoszenie kleju – urządzenie pozwala tworzyć pudełka w różnych stylach i formatach, bez konieczności stosowania wykrojników. Niezależnie od tego, czy tworzysz pudełka na potrzeby e-commerce, logistyki czy produkcji wielkoseryjnej – maszyna do produkcji opakowań kartonowych Boxmat HD dopasuje się do Twojego procesu.

Zemat Technology Group wspiera klientów nie tylko w wyborze odpowiedniego modelu, ale także w pełnej konfiguracji linii produkcyjnej. Nasi eksperci pomagają dobrać właściwe podajniki, systemy sztancujące, aplikatory kleju czy układy automatyzujące przepływ materiału. Dzięki temu ta wszechstronna maszyna do produkcji opakowań kartonowych może zostać dopasowana zarówno do produkcji jednostkowej, jak i seryjnej – niezależnie od wielkości zakładu czy branży.

Zapewniamy kompleksowy serwis – zarówno gwarancyjny, jak i pogwarancyjny – a także zdalną diagnostykę, szybkie wsparcie techniczne i dostęp do oryginalnych części. Nasze wieloletnie doświadczenie oraz inżynieryjna precyzja sprawiają, że każda inwestycja w technologię Zemat przekłada się na długofalową wydajność i bezpieczeństwo operacyjne.