box makers compare

UNIVERSELLE LÖSUNGEN IM KARTONAGENHERSTELLUNG

Finden Sie die perfekte Maschine, die Ihren Produktionsanforderungen entspricht!

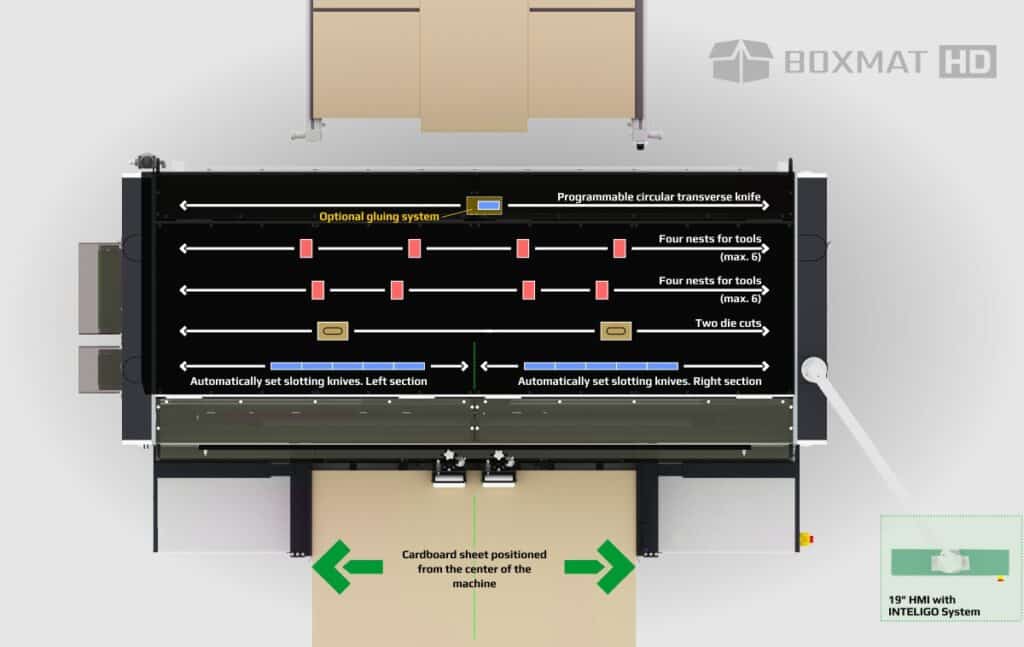

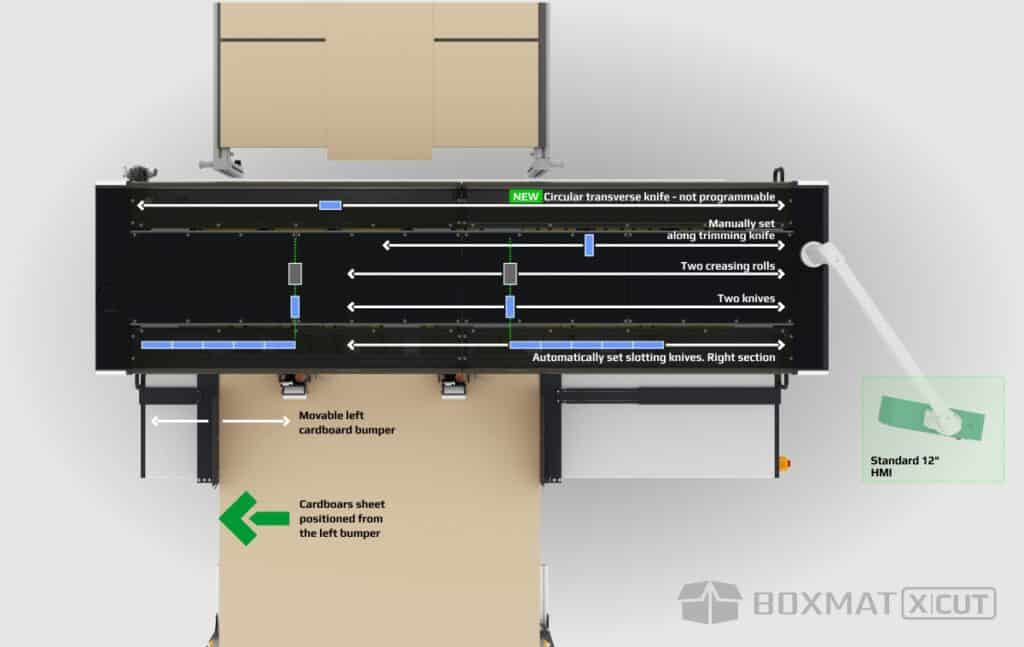

BOXMAT HD | BOXMAT PRO / BOXMAT PRO INTELIGO | BOXMAT XCUT |

|---|---|---|

Built in double die cutting system: 210 x 130 mm (8.25 x 5.1”) each | No die cutting | No die cutting |

Counter-scoring/creasing system (automatically set) | No counter-scoring/creasing system | No counter-scoring/creasing system |

Counter-knife system (automatically set)

| No counter-knife system | No counter-knife system |

Automatic recognition of a set tool (knife or scoring wheel) | Type of tool set from HMI | Tools installed permanently |

Independent servo-drive for each tool nest | One gripper to set up all tools | One mechanism for setting all tools |

Ability to set tools inline one after another. Double creasing lines available | Not available | Not available |

Detachable feeders (3 available): – standard feeder – vacuum feeder – special fanfold feeder | Standard non-detachable feeder | Standard non-detachable feeder |

Single/Double wall corrugated sheets or Fanfold/Z-fold (OPTION) | Corrugated sheets only

| |

4 (max. 8) cutting knives or blank formatting and cutting off glue flaps | 2 knives for cutting off glue flap, +1 knife for removing excess board

| |

Circular transverse knife for board length (cross-cut) adjustment | ||

Programmable movement of the transverse knife. Ability to cut revision flaps | Revision flaps non available | |

4 scoring wheels (max. 8) for along creasing | 2 scoring wheels for longitudinal scoring/creasing | |

Pressure for creasing/scoring wheels set from touch panel | Pressure for creasing/scoring wheels set with adjustment knob | |

Cardboard sheet positioned from the center of the machine | Cardboard sheet positioned to the left bumper | |

Working width: up to 2400 mm (94.5”) | Working width: up to 2500 mm (98.5”) | |

Knives and creasing wheels set automatically simultaneously | Knives and creasing wheels set automatically in series | Knife for removing excess set manually |

Pads production available | ||

Multiproduction: 2 or more from the length – standard | No multiproduction | |

Left/right blank sheet bumper set automatically | Right cardboard bumper set and locked manually | |

Interior LED lights | No interior LED lights | |

INTELIGO SYSTEM (only in Boxmat PROi): – Large 19” touch screen HMI – Expanded user friendly GUI – Box Design WIZARD interface – Job Queue System (JQS) production scheduling – Cut/Score Allowances correction and editing – Optional Integration with MRP/ERP manufacturing systems – Optional 3D scanning | Standard 12” touch screen HMI | |

Optional miniFLEXO available | Optional miniFLEXO not available | |

Optional Gluing System available | Optional Gluing System not available | |

Automatic FEEDER integration available | Automatic FEEDER integration not available | |

Box Folding integration available | Box Folding integration not available | |

Footprint (L x W x H): 3600 x 1900 x 1750 mm 142 x 75 x 69” | Footprint (L x W x H): 3300 x 1600 x 600 mm 130 x 63 x 63” | Footprint (L x W x H): 3300 x 1400 x 1600 mm 130 x 55 x 63” |