ROLLMAT

Roller die cutter for cardboard, hard foil, fabric

Programmable semi-automatic shuttle operation

Die cutter is designed for cutting out different patterns from hard foils, cardboard and paper. It can also be used for cutting out die stampings, from foils obtained in the vacuum forming process, by means of band punching dies placed on the plywood. It enables the so-called cardboard bending (making incisions) and perforation used in the production of foil and cardboard packing.

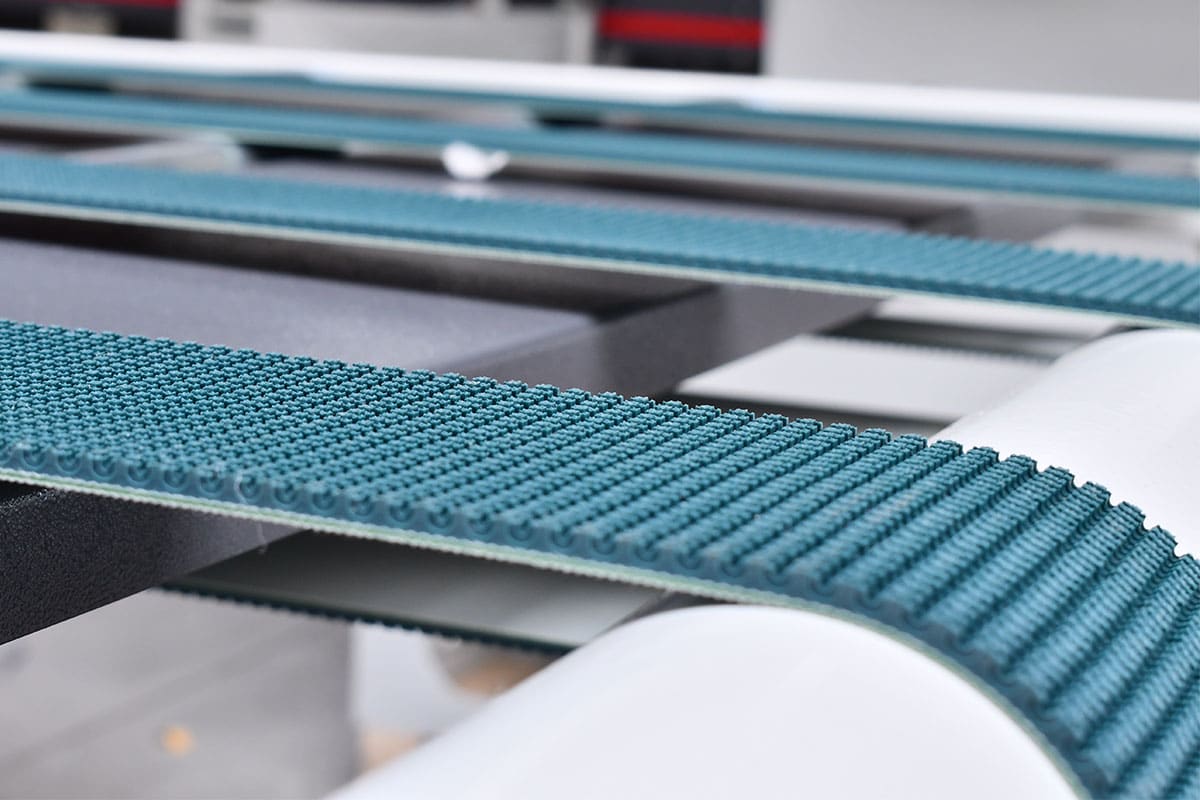

An upper shaft is covered with a special plastic material. Punching die (special wooden form with knifes) with a cut-out material is placed directly between die cutter shafts. This method increases the output of the machine. Die cutter shafts are driven by transmission belt, which enables noiseless and steady work. Tables are equipped with transmission belts placing the punching die between two die cutter shafts.

Zemat TG range of ROLLER DIE CUTTING machines has been developed to give companies the flexibility to produce short runs of die-cut boxes, quickly and easily. The ROLLMAT is set-up and ready to start producing boxes in seconds. The user can produce any size and design of box at a moments notice using a conventional wood form, cutting die.

With the ability to exert up to 150 tons of cutting pressure, the ROLLMAT can convert all types of corrugated board, solid fiberboard and plastics, giving exceptional flexibility. The use of a Mitsubishi PLC control system offers three modes of operation: single, double or automatic transfer. Depending on the level of production required, either one or two machine operators can be used.

Features:

- Max die height: 75mm (3”)

- Widths from 800mm (31”) to 2500mm (98”)

- Precision cutting with simple flat bed wood/steel blade dies

- Manual and automatic shuttle production cycles

- Production speed max: 20-30 cut cycles/min

- Programmable number of cycles

- Change from one die to the next in seconds

- Touch screen setup and PLC control

- Convert a range of materials from 0-12mm (1/2”) thickness

- Audible alarm signaling machine start

- Upper roller coated in high resistance polymer

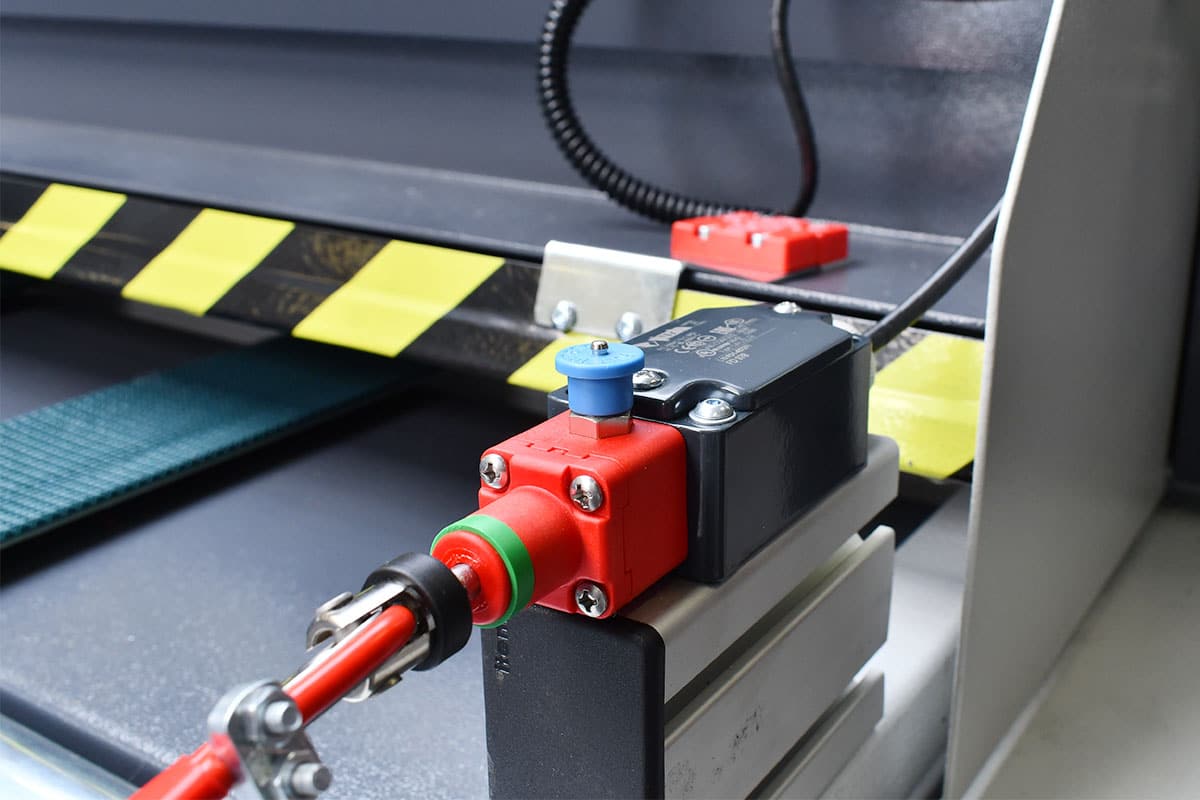

- Double safety system

- Compact and foldable design

ROLLMAT - Produce your own die-cut boxes in-house

Only minimal training required – no need for skilled labour

Applications:

- Packaging: clam shell, blister packs, inserts

- Stationery

- Nonwovens

- Leather and reinforced or laminated soft plastics

- Foams: full spectrum of various density foams up to 100mm thick

- Wall Solid Fibreboard: up to 5mm (3/16") (depending on density)

- Plastics: hard foils, PVC, PP, PET, PE, HDPE, Thermoformed films

- Corrugated boards: 2, 3 and 5-layers

Rollmat product

Rollmat product

Rollmat product

Rollmat product

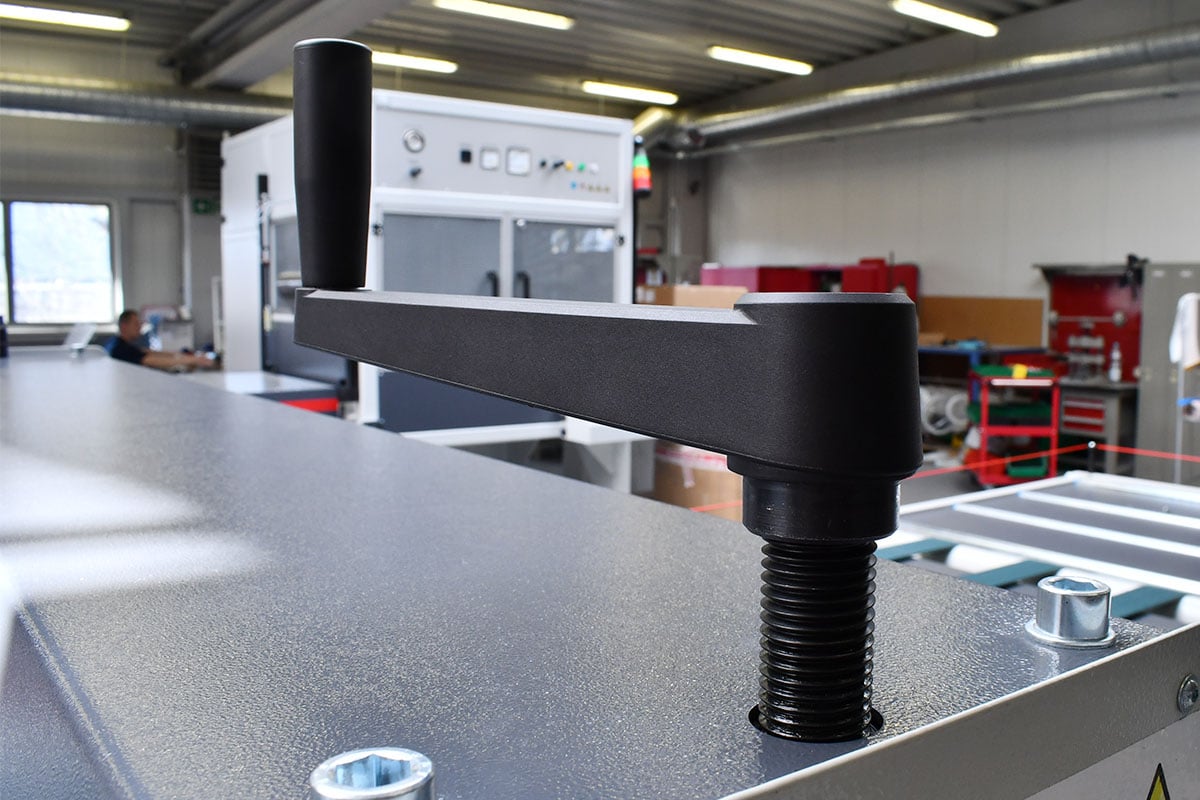

Details:

Roller die cutter

Roller die cutter

Roller die cutter

Roller die cutter

Technical Specification:

Working width : | 800 – 2500 mm |

Distance between shafts: | 0 – 100 mm |

Punching tool moving speed: | 0,7 – 0,8 m/s |

Cycle time: | 4-10 s |

Installed power: | 0,75 – 2,2 kW |

Shafts diameter: | 210/200 mm or 310/310 mm |

Length of each table: | 1600-3400 mm |