Machine for cardboard boxes production

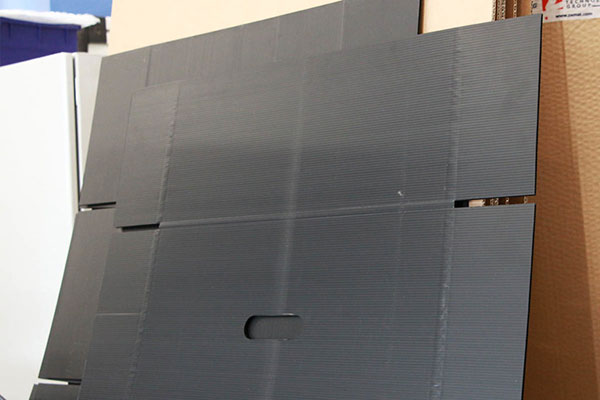

Boxmaker Boxmat X-CUT

No additional tools or dies required for operation

Boxmaker Boxmat X-CUT is an economical and versatile machine designed for short series corrugated boxes production and having an excellent price to performance ratio

Boxmat Boxmakers are modern machines providing such capabilities and ease of use while maintaining competitive and good price. Furthermore they allow to lower the logistics costs since there is no need to order large quantities of one size boxes to have low cost.

Straightforward yet highly adaptable machine, ideal for producing short runs of corrugated boxes. It offers an exceptional balance between price and performance

Features:

- Two-out multiproduction capability – you can make 2 boxes, one after another, from extended size board

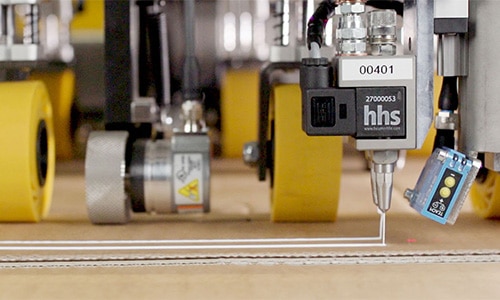

- Enhanced integration- optional miniFlexo printer and Gluing System

- Corrugated Board Compatibility: Supports B, C, and BC flutes.

- Precision Cutting: Ensures accurate board length adjustments

- Anti-Jam Design: Rear-mounted transversal cutting knife prevents board jamming

- Integrated Process: Slotting, cutting, scoring, creasing, and board trimming all performed in a single cycle.

- All-in-One Construction: Reduces production errors commonly associated with multi-modular machines.

- Quick Changeover: Less than 60 seconds required for changeover from style to style or size to size.

- Versatile Formatting: Supports both longitudinal and transverse board size adjustments.

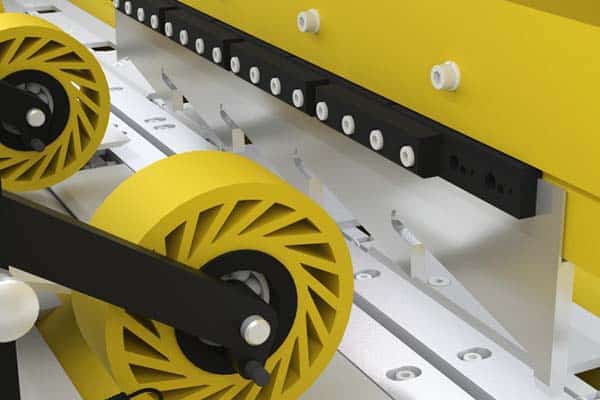

- Advanced Slotting: Equipped with 10 sectional slotting knives, each 100 mm wide.

- Creasing and Formatting: Features two creasing rolls and three longitudinal formatting knives

- Smooth Feeding: Board feeder with soft grip rolls for gentle handling.

- External Length Control: Provides precise external length control of the board.

Features:

- Glue Flap Cutting: Includes a mechanism for cutting off the glue flap.

- Remote Diagnostics: Secure built-in VPN connection allows for remote diagnostics and updates via HMI.

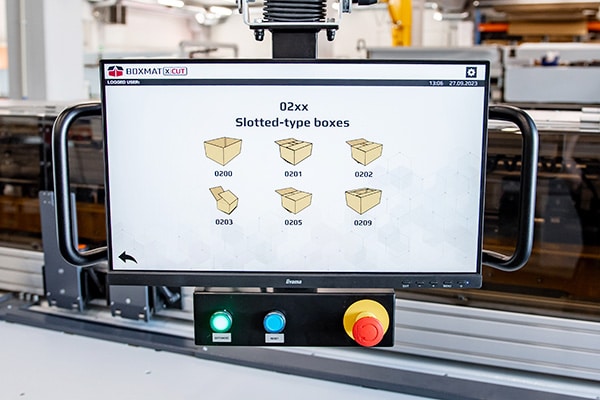

- User-Friendly Interface: Main box production settings controlled through a 21.5” intuitive touch screen panel.

- Versatile Box Design: Preloaded with 40+ FEFCO styles and a Free Style option for custom box designs.

- Tool-Free Operation: No additional tools or dies required for operation.

- Semi-Automatic Setup: Streamlined setup process with semiautomatic features.

- Energy Efficient: Operates on an ecofriendly, low-energy power supply.

- High Productivity: Capable of producing up to 600 boxes per hour.

- Sectional Slotting: Utilizes sectional slotting knives for precise cutting.

- Electric Drives: Most settings are adjusted electronically.

- Manual Adjustments: Knife trimming and creasing/scoring pressure are manually set with adjustment knobs

- Alignment Precision: Blank sheets are positioned against the left edge with an automatically set bumper.

- Stable Operation: Equipped with vibration absorbing support feet for stable performance

- Sectional slotting knives

- Sheet placed to the LEFT edge of the machine

- NEW! 22" touch screen HMI

BOXMAT X-CUT - The Perfect Boxmaking Machine!

Boxmat X-CUT: The Next Generation Boxmaker for Corrugated Box Production

The Boxmaker Boxmat X-CUT is an advanced solution in the world of corrugated box production. As the evolution of the successful Boxmat 2 model, it now features a completely redesigned look inspired by the flagship Boxmat HD model. While retaining all the functionalities of its predecessor, the Boxmat X-CUT introduces significant innovations that enhance both performance and user experience.

Unmatched Versatility for Short to Medium Production Runs

The Boxmat X-CUT is engineered for producing corrugated cardboard boxes in short to medium production runs. It is capable of creating virtually any size and style of box, with a setup time of less than 60 seconds. This boxmaker seamlessly transitions between different box types—from small, regular cartons to large wraps and pallet boxes.

The Boxmaker Boxmat X-CUT is particularly suited for companies that require flexible, in-house production of corrugated boxes. With its ability to quickly and frequently change box sizes and types, it’s a game-changer in the packaging industry. The machine performs slitting, creasing, excess board removal, and glue flap trimming in a single, efficient pass—eliminating the need for additional modules. It can handle both single and double wall corrugated cardboard, ensuring maximum adaptability.

Innovative Cutting Technology for Maximum Efficiency

One of the standout features of the Boxmaker Boxmat X-CUT is its integrated cross-cutting knife, which allows for precise cutting without the need for pre-cutting. This innovative design ensures that the machine handles longitudinal and transverse trimming in a single operation, greatly enhancing user convenience and overall performance.

Whether producing a single box or hundreds, the Boxmat X-CUT delivers efficient and precise results. It can accommodate cardboard dimensions up to 2500 x 10000 mm, making it ideal for the effortless production of large boxes. All machine settings are easily controlled through a 21.5” touch screen panel, which includes approximately 40+ preprogrammed FEFCO box styles.

Operators can also utilize the Free Style mode to customize box designs to specific needs. The machine’s memory can store up to 1,000 recipes, enabling quick retrieval of previously made products. The dedicated software is intuitive and user-friendly, ensuring that even new operators can quickly learn to operate the machine.

Enhanced Precision and Board Handling Capabilities

The Boxmat X-CUT ensures precise board positioning with an automatically set bumper on the left edge, allowing for accurate cutting of excess cardboard and glue flaps. The new crosscut knife eliminates the need for pre-cutting, streamlining the production process. Soft grip rolls and robust input/output shafts maintain precision control of board feeding, preventing skewing and ensuring smooth processing of both small and large blanks.

The slotting and creasing assembly features a hardened steel feeding roll, which improves precision and extends productivity. Special sectional knives handle slitting with 10 knives (each 100 mm long) as standard—5 in both the left and right sections. The length of these sections can be adjusted by adding or removing knives, providing a range of 200 to 700 mm for customized slitting requirements.

Boxmat X-CUT – The Ultimate Boxmaker for Efficient Production

The Boxmaker Boxmat X-CUT represents the latest in corrugated box production technology, offering unparalleled flexibility, precision, and ease of use for companies seeking efficient in-house box manufacturing solutions. Its innovative cutting technology and user-friendly interface make it the ideal choice for businesses aiming to optimize their box production processes.

Available boxes:

Technical Specification:

Cardboard used: | Single or double wall B, C, BC |

Types of boxes: | Preinstalled ~60 FEFCO styles + Free Style |

Power supply: | 3 x 400 V (USA: 230 V /20 A) |

Minimum board size: | 350 x 550 mm (14 x 21”) |

Maximum board size: | 2500 x 10000 mm (98 x 393”) |

Min./max. distance between slotting knives | 60-1500 mm (2 3/8”-59”) with 500 mm knives |

Slot width: | 8 mm (5/16″) |

Sectional slotting knives: | 100 mm (4”) each section |

Standard slotting knives length: | 500 mm (20”) each side |

Min/max slotting knives length | 200-700 mm (8-27½”) |

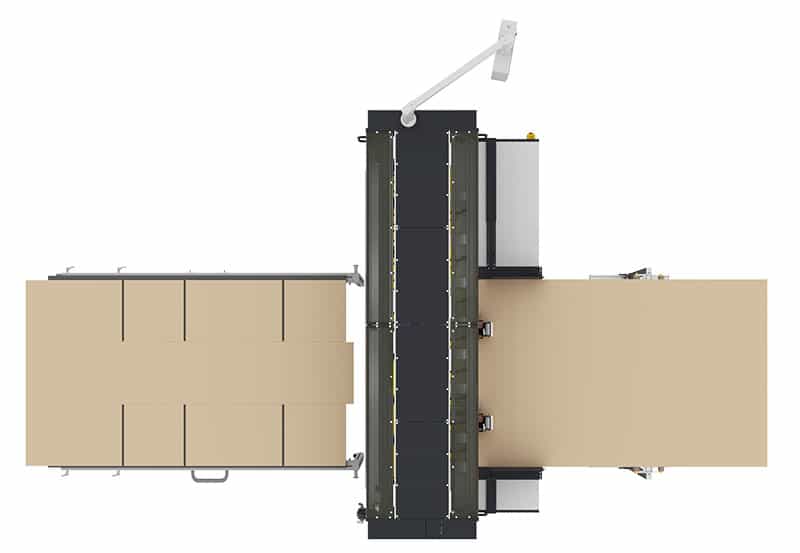

Footprint (L x W x H): | 3350 x 1550 x 1550 mm (140 x 61 x 61”) |

Weight: | 2300 kg |

Features and benefits

- Blade knives – depending on the application

- Slotting knives for precision box shaping

- Coroplast compatibility – allows production of corrugated plastic boxes

- Intuitive HMI with built-in Box Creation Wizard