In today’s dynamic packaging industry, the need for fast, efficient, and versatile solutions is more urgent than ever. To meet these needs, Zemat Technology Group has developed the innovative BOXMAT line of machines, revolutionizing corrugated packaging production. But why are customers so eager to choose these machines?

Versatility and Efficiency in Packaging Production

One Machine for Many Tasks

BOXMAT machines, such as the BOXMAT HD, BOXMAT PROi, and BOXMAT XCUT, are renowned for their extraordinary versatility. They can perform multiple operations—from cutting, creasing, and scoring to gluing—all in one cycle. This means companies can produce various corrugated boxes packages quickly and precisely without investing in multiple devices.

Flexibility in Box Production

Customers appreciate the ability to adapt the machines for short production runs, which is crucial in today’s volatile market. These machines allow for quick switching between different types of boxes, increasing efficiency and reducing downtime.

Modern Technologies

Module Connect System

BOXMAT BOXMAKERS offer advanced technology alongside versatility. These machines use the Module Connect system, enabling quick and secure connection of machine modules, simplifying maintenance and upgrades.

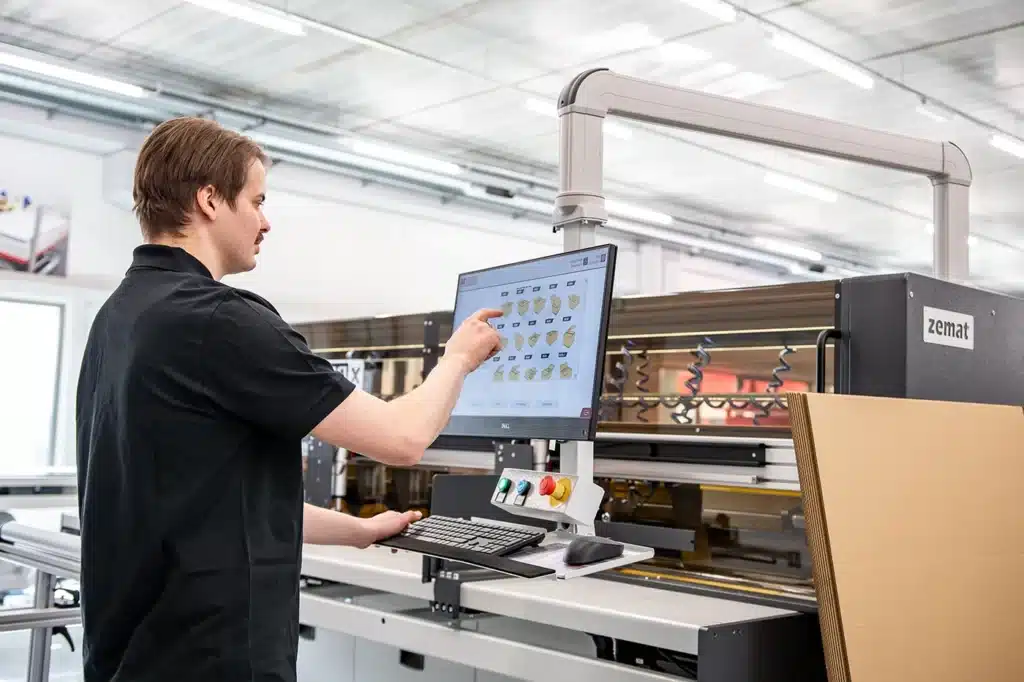

Inteligo HMI System

The Inteligo System allows for advanced monitoring and management of production processes, significantly increasing efficiency and precision. Integration with ERP systems further automates production processes, minimizing errors and boosting productivity.

Compact Design and Ease of Integration

Space Saving

BOXMAT machines are also valued for their design, which facilitates integration with existing production lines. This enables companies to seamlessly implement new devices into their processes without disrupting work or incurring additional costs associated with reorganizing production space.

Ease of Use

Additionally, the ease of use of these machines means that employees can quickly learn to operate them, minimizing training time and downtime. Intuitive user interfaces and access to fast technical support make operating BOXMAT packaging machines simple and efficient.

Increased Productivity and Cost Reduction

Process Automation

One of the greatest advantages of BOXMAT machines is their ability to significantly increase productivity. Automating many processes, such as cutting, creasing, scoring and gluing, reduces the need for manual operation and supervision. This in turn, lowers operational costs and minimizes production errors.

Quality Improvement

Customers often highlight that after implementing BOXMAT machines, they noticed a significant increase in the number of boxes produced and an improvement in the quality of final products. Process automation eliminates human errors, resulting in more uniform and precise packaging.

Positive Customer Feedback

High User Satisfaction

User feedback on BOXMAT machines is overwhelmingly positive. Customers appreciate not only the increased productivity and production flexibility but also the precision and quality of corrugated packaging. The high quality of technical support provided by Zemat Technology Group is also frequently mentioned as a significant factor influencing customer satisfaction.

Professional Approach

Quick response to problems and a professional approach to customers make companies feel confident and able to focus on their production goals. Long-term customer relationships and an individualized approach to their needs further increase user loyalty.

Future and Innovations

Introduction of BOXMAT PRO X

Zemat is not resting on its laurels. In the second half of 2024, the company plans to introduce the new BOXMAT PRO X machine, equipped with even more advanced production features. The new model will enable more complex operations, contributing to further increasing the production efficiency of customers and strengthening Zemat’s position as a leader in the cardboard packaging machinery market.

Continuous Technological Development

The company invests in research and development, striving to continuously improve its products. Introducing innovations and responding to changing market needs are key elements of Zemat Technology Group’s strategy, ensuring their competitive advantage.

Boost Your Production Efficiency with BOXMAT Machines

BOXMAT machines are the answer to the growing demands of the packaging industry. Their versatility, advanced technologies, compact design, and process automation capabilities make them the ideal choice for companies seeking to increase production efficiency and reduce costs. Positive customer feedback and ambitious future plans only confirm that Zemat Technology Group is on the right path to further development and introducing more innovations to the market.

FAQ

What makes BOXMAT machines so versatile? BOXMAT machines can perform multiple operations—from cutting, creasing, and scoring to gluing—in one cycle, allowing for the production of various cardboard packages without investing in multiple devices.

Are BOXMAT machines easy to operate? Yes, BOXMAT machines are designed to be easy to operate. Intuitive user interfaces and access to fast technical support make operating these machines simple and efficient.

What are the benefits of automating production processes with BOXMAT machines? Automating production processes with BOXMAT machines increases productivity, lowers operational costs, minimizes production errors, and improves the quality of final products.

What do customers think about BOXMAT machines? Customers express positive opinions about BOXMAT machines, appreciating their productivity, flexibility, precision, and the quality of packaging. The high quality of technical support is also frequently mentioned as an important factor influencing customer satisfaction.

What are Zemat Technology Group’s development plans? Zemat Technology Group plans to introduce the new BOXMAT PRO X machine in the second half of 2024, equipped with even more advanced production features. The company also invests in continuous technological development, striving to improve its products and introduce innovations.