Cost-Saving Solution for Corrugated Cardboard Box Production

Short series production with excellent cost-efficiency

No additional tools or dies

– designed for simplified operation

Cost-Effective Solution for Corrugated Cardboard Box Production

The Boxmat X-CUT is an efficient and economical machine designed specifically for corrugated cardboard box production in short and medium series. With a focus on usability, speed, and affordability, it offers the perfect balance between price and performance for companies seeking independence from external packaging suppliers.

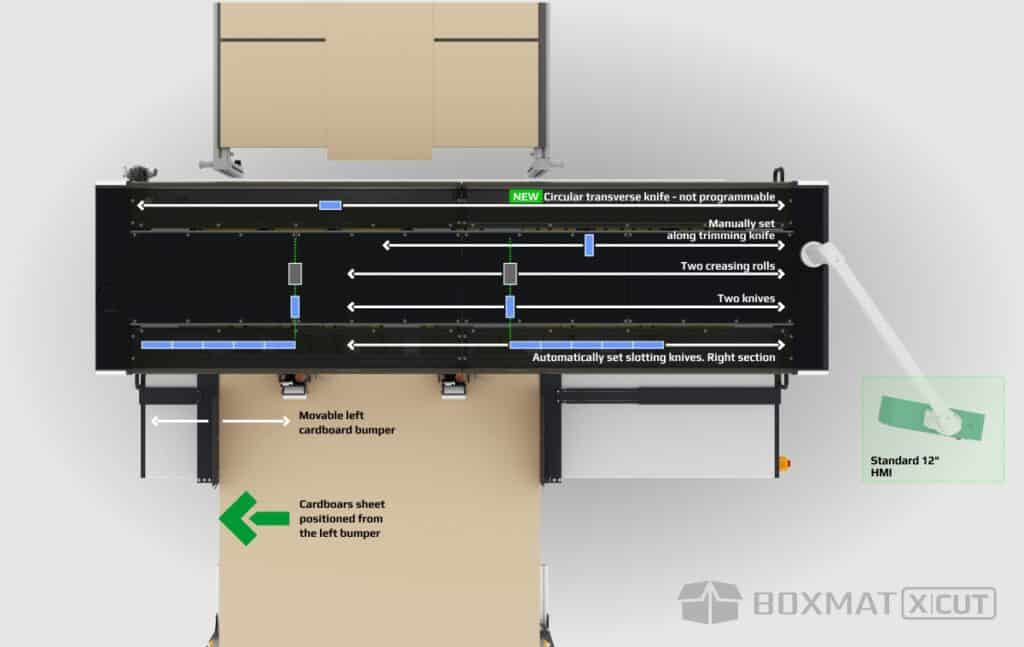

This corrugated cardboard box production system supports full-cycle manufacturing – slotting, creasing, cutting, trimming and flap removal – all completed in a single pass. Thanks to its advanced cutting technology and easy-to-use interface, the Boxmat X-CUT requires no additional tools or dies, making it ideal for frequent size changes and small-batch production.

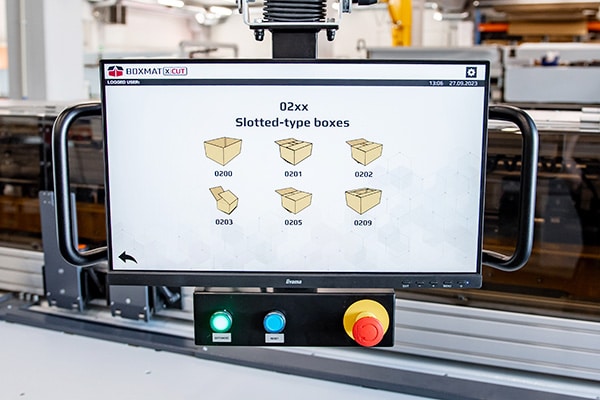

The machine is compatible with single and double wall boards (B, C, BC) and offers over 40 preinstalled FEFCO styles, along with Free Style mode for custom box design. With fast setup times, intuitive touchscreen control and a sturdy, compact design, it delivers unmatched efficiency in corrugated cardboard box production without the complexity of modular systems.

Whether you’re producing standard shipping boxes, wraps, or custom packaging, Boxmat X-CUT gives you full control over your process – helping reduce lead times, eliminate overstock, and optimize your packaging operations.

BOXMAT X-CUT - Smart investment in corrugated cardboard box production

Key Features

- No additional tools or dies required

– all settings are servo-driven and tool-free - Quick changeover

– less than 60 seconds between different box styles or sizes - Precision cutting

– accurate board length adjustment and cross-cutting in a single pass - Two-out multiproduction

– produce two boxes in sequence from extended-size board - Versatile formatting

– supports both longitudinal and transverse board size adjustments - User-friendly interface

– intuitive 21.5” touch screen panel with simple operation - 40+ preinstalled FEFCO styles

– plus Free Style mode for custom box designs - Remote diagnostics

– built-in VPN connection for updates and service access - Energy efficient

– eco-friendly low-power operation for reduced production costs

Efficient corrugated cardboard box production – simplified and cost-effective

Take your packaging in-house with Boxmat X-CUT – a reliable solution for corrugated cardboard box production that combines functionality, precision, and affordability. Designed for companies looking to reduce costs without compromising on performance, this boxmaker delivers everything you need for short-run production in one streamlined machine.

With no need for additional tools or dies, quick changeovers, and intuitive operation, Boxmat X-CUT makes producing custom boxes simple and efficient. Whether you’re fulfilling individual orders, small batches, or frequent format changes, it supports agile production with minimal investment and maximum control. Perfect for businesses seeking flexibility, independence, and value, this machine offers a smart entry point into corrugated cardboard box production – without the complexity or high cost of fully automated systems.

Solution for Corrugated Cardboard Box Production

BOXMAT X-CUT: Features

- Corrugated board compatibility: Supports B, C, and BC flutes (single and double wall)

- High productivity: Up to 600 boxes per hour

- Glue flap cutting mechanism for clean edge finishing

- Anti-jam design with rear-mounted transversal cutting knife

- Integrated slotting, scoring, creasing, cutting, and trimming in one pass

- Tool-free operation: No additional tools or dies required

- Semi-automatic setup for faster operations

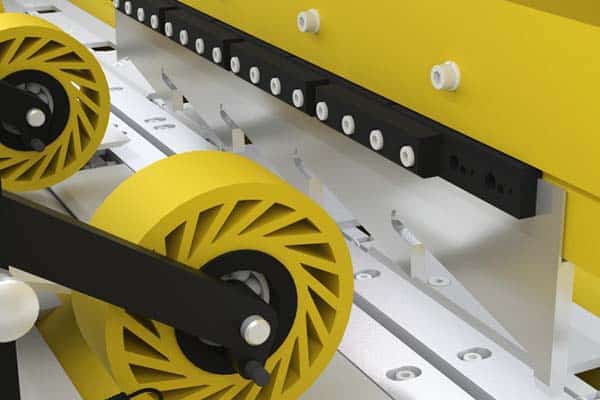

- Advanced slotting: 10 sectional knives (5 left, 5 right) – each 100 mm wide

- External board length control with precise adjustment

- Manual knobs for trimming and creasing/scoring pressure

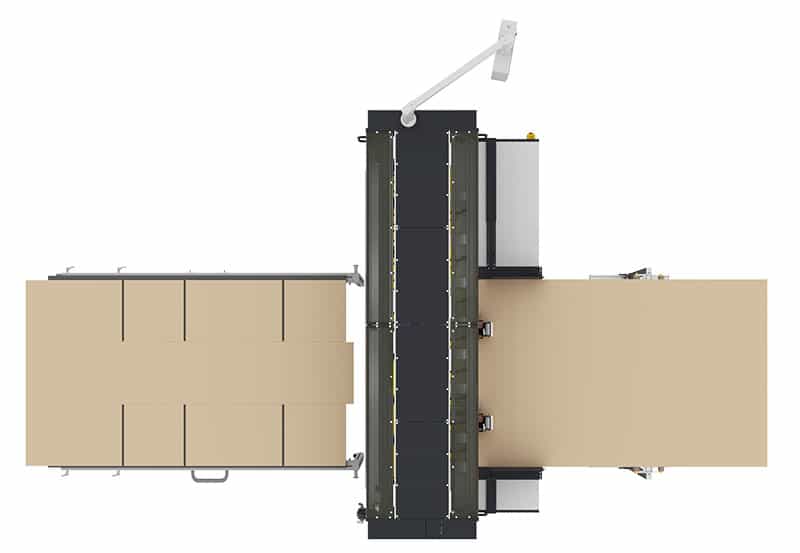

- Smooth feeding: Soft grip rolls for gentle board handling

- Blank sheets aligned on the left edge with automatic bumper

- Electric drives for most setting adjustments

- Stable operation ensured by vibration-absorbing support feet

- Versatile box design: 40+ FEFCO styles + Free Style custom mode

- Memory for up to 1000 box design recipes

- Integrated 21.5” touch screen for intuitive control

- Compatible with optional miniFlexo printer and gluing system

- All-in-one construction: fewer modules, fewer errors

- Eco-friendly, low-energy power supply (3 x 400 V)

- Sectional slotting knives

- Sheet placed to the LEFT edge of the machine

- NEW! 22" touch screen HMI

Technical Specification:

Cardboard used: | Single or double wall B, C, BC |

Types of boxes: | Preinstalled ~60 FEFCO styles + Free Style |

Power supply: | 3 x 400 V (USA: 230 V /20 A) |

Minimum board size: | 350 x 550 mm (14 x 21”) |

Maximum board size: | 2500 x 10000 mm (98 x 393”) |

Min./max. distance between slotting knives | 60-1500 mm (2 3/8”-59”) with 500 mm knives |

Slot width: | 8 mm (5/16″) |

Sectional slotting knives: | 100 mm (4”) each section |

Standard slotting knives length: | 500 mm (20”) each side |

Min/max slotting knives length | 200-700 mm (8-27½”) |

Footprint (L x W x H): | 3350 x 1550 x 1550 mm (140 x 61 x 61”) |

Weight: | 2300 kg |

Corrugated Cardboard Box Production – Setup, Optimization and Support

The Boxmat X-CUT is an efficient and economical solution for corrugated cardboard box production, ideal for short series and custom packaging needs. Designed for companies looking to take control of their box manufacturing process, it combines essential features with intuitive operation and outstanding value. Whether you’re starting in-house packaging or searching for a flexible backup solution, Boxmat X-CUT delivers precision and reliability without the complexity of larger systems.

At Zemat Technology Group, we support every stage of corrugated cardboard box production – from choosing the right configuration to long-term machine servicing. Our team helps you select the right setup for your needs, including optional features like gluing systems or printing integration. We ensure that your Boxmat X-CUT fits seamlessly into your packaging line, delivering measurable savings and performance from day one. With remote diagnostics, expert support, and original parts always available, we make sure your investment in corrugated cardboard box production continues to deliver – efficiently, reliably, and on your terms.