The most versatile corrugated box making machine

for high-density and fanfold board production

The most advanced corrugated box making machine in our range – designed for flexibility and heavy-duty performance.

Boxmat HD is our most advanced and versatile corrugated box making machine, engineered to process high-density corrugated board and fanfold materials with precision and efficiency. It’s the ideal solution for manufacturers looking to reduce reliance on third-party packaging suppliers and take full control of their box production.

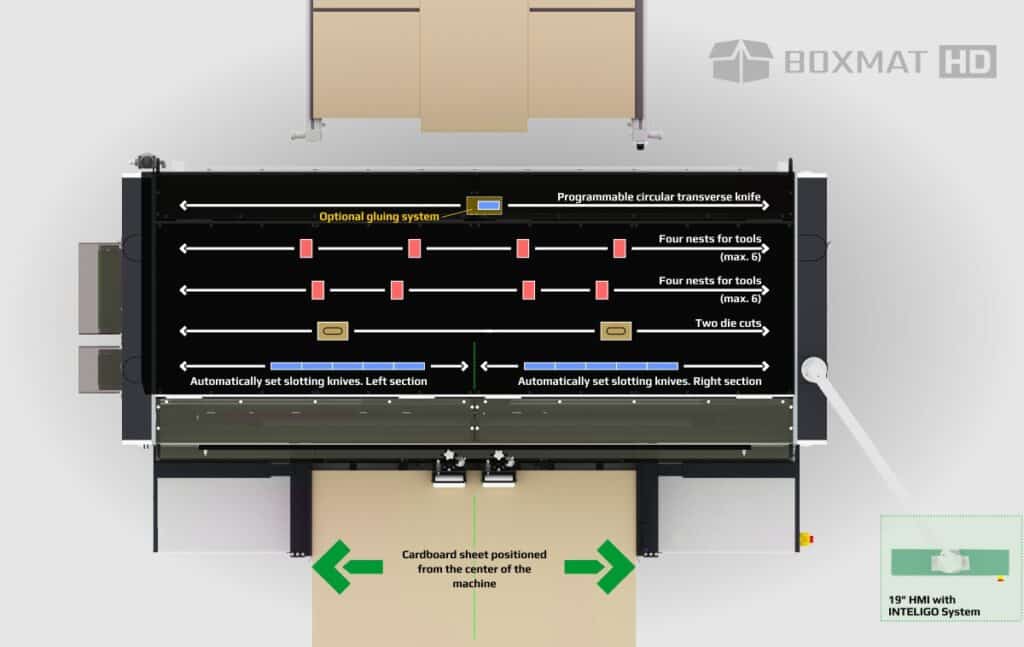

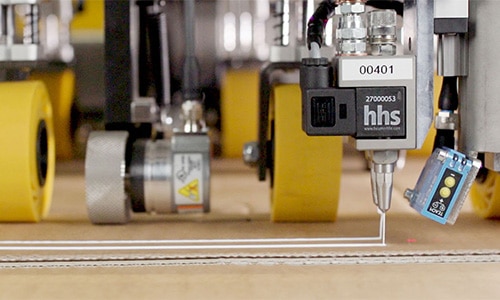

With an integrated die-cutting unit and an optional gluing system, Boxmat HD offers complete production flexibility – from simple FEFCO styles to complex, custom-designed boxes. The machine supports both manual sheet feeding and full automation, making it suitable for short runs, just-in-time production, or integration into large-scale, fully automated packaging lines.

As a high-performance corrugated box making machine, Boxmat HD adapts to your current needs and evolves with your business – whether you operate in e-commerce, logistics, industrial manufacturing or contract packaging.

BOXMAT HD - High-Performance Corrugated Box Making Machine

Key Features:

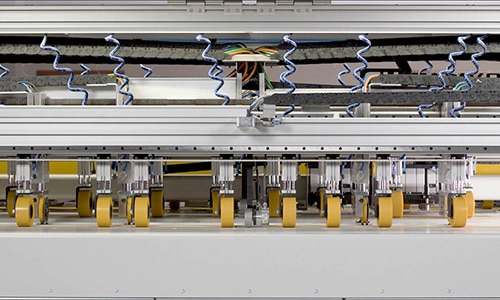

- Optimized construction of longitudinal tools – reduced minimum distance between tooling heads

- Possibility to use double creasing rolls for improved fold precision

- Automatic identification of tooling – advanced system detects tool type on the beam

- Over 40 pre-installed FEFCO styles and 100+ box design variations

- One-pass box production – cutting, creasing and shaping in a single cycle

- Capable of processing single-wall, double-wall and heavy-duty corrugated board

- Supports both sheets and fanfold materials

- Built-in die-cutting module and optional gluing system

-

All-in-one corrugated box making machine

– designed for flexibility, speed and precision - Quick changeover – less than 30 seconds

- Independent servo-driven setup of all tools

- Precision counter-knife and counter-creasing system

- Large and intuitive 19” touchscreen interface

Integrated Inteligo System:

- JQS Job Queue System for production scheduling

- Box Design Wizard (graphical box editor)

- Integration with ERP/MRP systems

- Barcode reader for automatic job selection

- Optional 3D product scanning and real-time cut/score adjustments

Full independence in corrugated packaging production!

With Boxmat machines, there’s no need to commit to long-term contracts with box suppliers. Our versatile corrugated box making machine gives you complete freedom – use any corrugated board supplier and produce custom boxes exactly when you need them, in the quantity you require.

Whether you’re managing seasonal demand, fulfilling individual orders, or testing new packaging formats, the Boxmat HD empowers you to stay flexible and in control. This corrugated box making machine eliminates unnecessary storage costs, reduces lead times, and allows you to respond instantly to market needs – all while maintaining full control over your production process.

Corrugated box making machine

BOXMAT HD – Features:

- Fully programmable interface for box creation in any style and size

- Detachable precision cardboard feeder – the corrugated box making machine can be configured for manual feed, printer integration or full automation, depending on current and future production needs

- New beam design significantly reduces slotting knife wear

- Works with both corrugated sheets and fanfold board

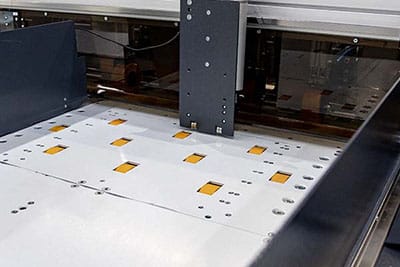

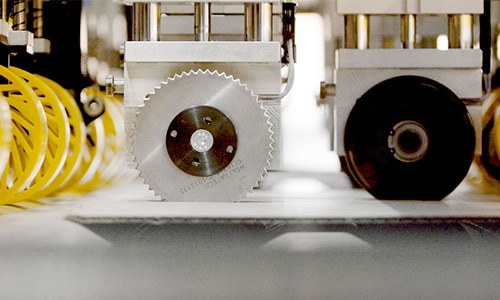

- Double die-cutting system with independent drives and two cutting heads (210 x 130 mm / 8.25 x 5.1”) for handles, cutouts or angled corners

- Reinforced chassis construction minimizes vibrations during operation

- Additional shaft for feeding corrugated board

- Independent servo drive for each tooling station enables fast and precise positioning

- Each tool station can accommodate either creasing wheels or cutting knives

- Minimum distance between tools: 30 mm (1.18”)

- Synchronized counter-creasing and counter-knife system

- Tools can be aligned in a single line (e.g. for double creasing heavy-duty boards)

- Built-in secure VPN for remote calibration, diagnostics and software updates

Sheets or fanfold board:

- Die-Cutting System

- The die-cutting system is mounted on an additional built-in beam and includes two independent die-cutting units, each with a working area of 210 x 130 mm (8.25 x 5.1”). Each unit has its own drive for precise positioning. Ideal for cutting handles, inspection windows or angular cuts in corrugated box panels, this module enhances the versatility of the corrugated box making machine.

- Optional Output Table

- Freestanding construction

- Lockable casters for stability and mobility

- Adjustable length to fit different box sizes

- Foldable design for easy storage and space-saving

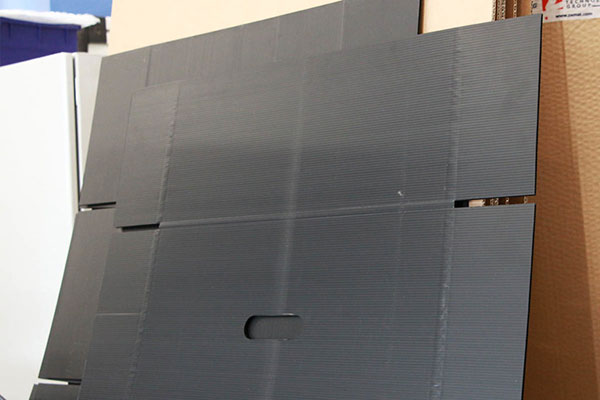

Sample boxes:

Features and benefits:

- Independent servo drive for each tool nest – ensures very fast and precise positioning

- Optional vacuum feeder for smooth, automated sheet feeding

- Coroplast compatibility – allows production of corrugated plastic boxes

- Adjustable double creasing rolls for heavy or multi-layer boards

- Circular or blade knives – depending on the application

- Slotting knives for precision box shaping

- Intuitive HMI with built-in Box Creation Wizard

- Fast tool setting with individual servo drives

- Conveyor waste/scrap removal system – for cleaner, uninterrupted operation

- Integrated die-cutting system for handle and custom cutouts

- Counter-crease and counter-knife system for enhanced scoring accuracy

Optional LWF Scissor Lift Feeder

- The LWF feeder provides automatic pick-up of corrugated sheets from a palletized stack using pneumatic vacuum suction cups

- A scissor lift mechanism automatically adjusts the height of the stack to match the pick-up level

- The distance between suction cups is manually adjustable based on the sheet width

- The feeder is fully integrated with Boxmat series machines, ensuring synchronized, collision-free feeding of sheets into the working area

- Maximum stack height: 900 mm (including pallet)

- Maximum sheet size: 1500 mm (width) × 2500 mm (length)

- Minimum sheet size: Depends on the specifications of the connected Boxmat model

Technical Specification

Supported materials: | Single-wall and double-wall corrugated board (B, C, EB, BC flute types) |

Box styles: | ~40 pre-installed FEFCO styles + Box Creation Wizard |

Power supply: | 3 × 380/415/480 V |

Minimum board size: | 250 mm (10″) width × 750 mm (30″) length |

Maximum board size: | 2400 mm (94″) width × 9999 mm (394″) length |

Slotting knife distance (min/max): | 75 – 2000 mm (3″ – 79″) with 200 mm knives

|

Slot width: | 7 – 8 mm |

Slotting knives segments: | 100 mm (4″) each |

Standard slotting knives length: | 500 mm (20″) left and right |

Available knife lengths: | 200 – 700 mm (8″ – 27.5″) |

Glue flap: | from 5 mm (3/16″) |

Machine dimensions (L × W × H): | 3600 × 1900 × 1750 mm (142″ × 75″ × 69″) |

Weight: | approx. 3800 kg (8370 lbs) |

Corrugated Box Making Machine – Consultation, Configuration, Service

The Boxmat HD is the most advanced and versatile corrugated box making machine in our portfolio. It’s an ideal solution for production facilities that require high automation and the ability to process heavy-duty corrugated board. With a wide range of built-in features – from die-cutting to gluing – the machine allows for the creation of boxes in multiple styles and sizes, without the need for dedicated cutting dies. Whether you’re producing boxes for e-commerce, logistics or high-volume manufacturing, the Boxmat HD adapts seamlessly to your production process.

At Zemat Technology Group, we support our clients not only in choosing the right machine model, but also in configuring the entire production line. Our experts assist in selecting feeders, die-cutting systems, glue application modules and material handling automation. This makes the Boxmat HD a flexible corrugated box making solution – perfectly suited for both short-run and large-scale production, regardless of the size or industry of your facility.

We offer full-service support – from warranty and post-warranty service to remote diagnostics, fast technical assistance and access to genuine spare parts. With decades of experience and engineering precision, every investment in Zemat technology delivers long-term performance, reliability and operational safety.