Corrugated Box Maker Machine for Short and Medium Runs

Flexible configuration with multiple feeder options

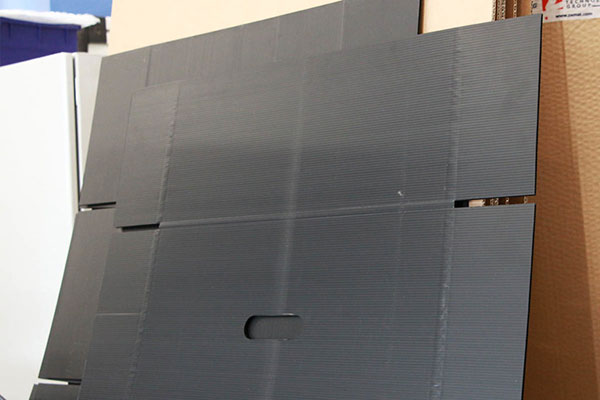

Corrugated box maker machine built for short and medium runs – efficient, flexible, and ready for real-world packaging needs.

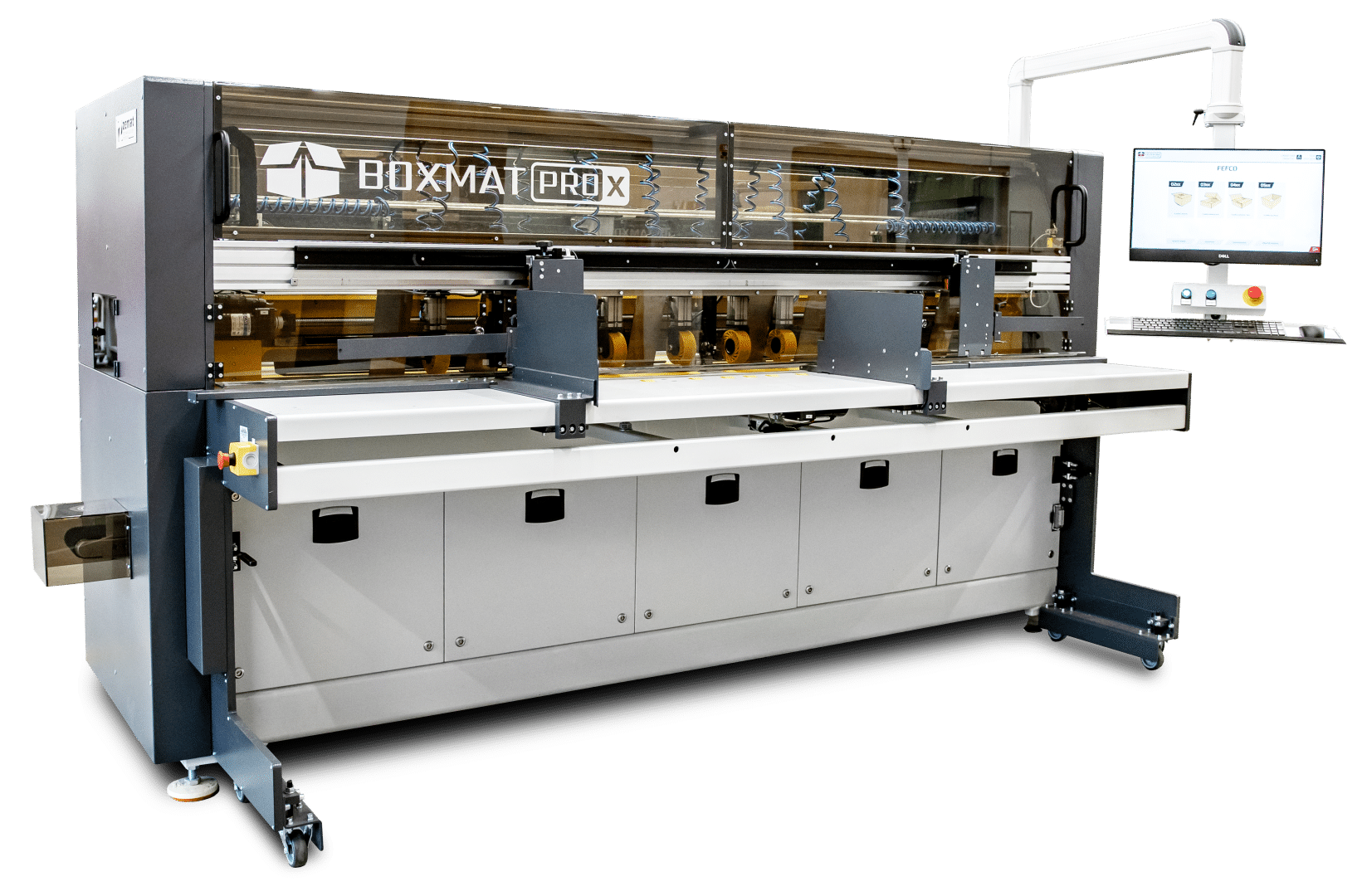

Boxmat PRO X is the next evolution of our bestselling boxmaker, designed to give manufacturers full control over packaging in low and mid-volume workflows. This corrugated box maker machine offers rapid changeovers, compatibility with multiple feeder types, and reliable performance – making it a smart choice for businesses that need flexibility without compromising speed or precision.

This corrugated box maker machine features a reinforced frame, a user-friendly 24” touchscreen interface, and full compatibility with a wide range of detachable feeders and box collection tables. The updated feed system and tool adjustment mechanisms make it ideal for producing both standard and custom FEFCO styles with precision.

Boxmat PRO X enables on-demand box production without the need for cutting dies, supporting efficient slotting, scoring, cutting, and gluing in a single workflow. Whether you’re serving e-commerce, logistics, or manufacturing clients, this corrugated box maker machine helps reduce lead times and eliminate packaging outsourcing.

BOXMAT PRO X - Corrugated box maker machine for smart, flexible production

Key Features

- Plug-n-Play Module Connect for seamless integration with Digital Printer and Feeders

- 24” touch screen HMI with a redesigned, intuitive interface

- Reinforced slotting beam for added durability and precision

- Improved longitudinal tools – faster setup and better alignment

- Built-in conveyor for efficient slotting waste removal

- Electrical adjustment of the feeding gap for enhanced material control

- Quick-access maintenance solutions for minimal downtime

- Upgraded modern design consistent with the latest Boxmat line

- Full compatibility with optional feeders

- Synchronization with Gluing System and miniFLEXO printing

- Option for hot glue application system

- Built-in INTELIGO System for smart diagnostics and control

Integrated Inteligo System

- JQS Job Queue System for production scheduling

- Box Design Wizard (graphical box editor)

- Integration with ERP/MRP systems

- Barcode reader for automatic job selection

- Optional 3D product scanning and real-time cut/score adjustments

- Cut/Score Allowances correction and editing

Total flexibility in short and medium-run packaging

Take full control of your packaging production with Boxmat PRO X – a powerful and intelligent corrugated box maker machine designed to meet the demands of custom, just-in-time production. No more dependency on third-party suppliers or excessive stockpiling. Boxmat PRO X lets you produce exactly the type and quantity of boxes you need, when you need them. Whether you’re handling short series, seasonal spikes, or personalized packaging, this corrugated box maker machine adapts to your workflow with precision, speed, and minimal setup time. Stay agile, reduce costs, and accelerate your time-to-market – with Boxmat PRO X, independence in box production becomes your new standard.

Corrugated box maker machine

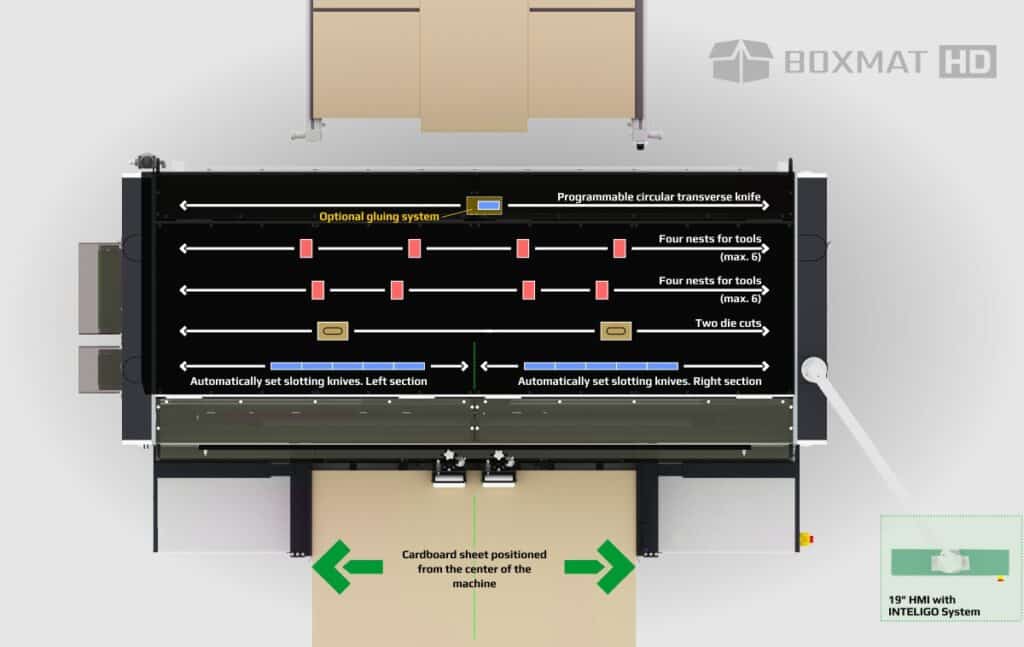

BOXMAT PRO X – Features

- Compatible with corrugated board types B, C, BC + fanfold

- Eco Drive servo motion for reduced power consumption

- 10 sectional slotting knives

- 4 cutting knives (expandable to 8)

- 4 scoring/creasing wheels (expandable to 8)

- External control of box dimensions

- Modify standard FEFCO styles (RSC/OPF/FPF) and create custom boxes

- Secure VPN remote diagnostics and software updates

- No need for tooling – all settings managed via servo drives

- Optional custom-shaped scoring/creasing wheels

- Supports multi-out production (multiple boxes from one sheet)

- All operations set from a single, intuitive touch screen panel

- Modular build for fast replacement of knives and creasing tools

- Integrated cycle: slotting, creasing, cutting, gluing, printing (with all options installed)

- FreeStyle mode – design custom boxes from scratch

- Compatible with Flexomat full-size flexographic printer

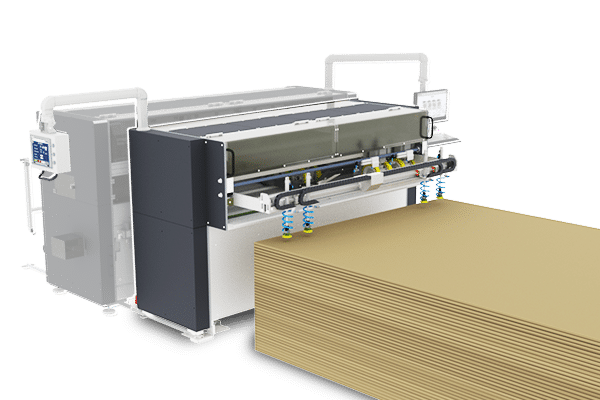

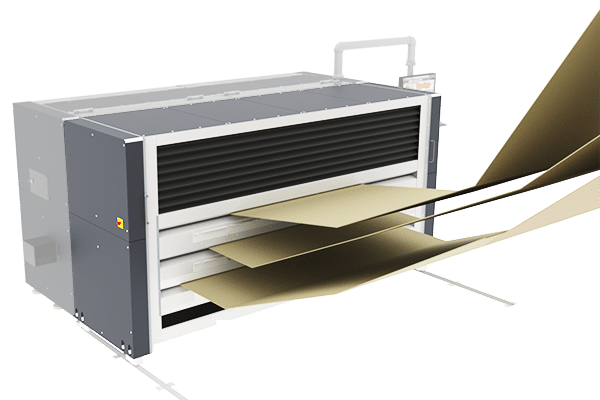

Sheets or fanfold board

SEAMLESS COMPATIBILITY WITH MULTIPLE FEEDERS AND ADD-ONS

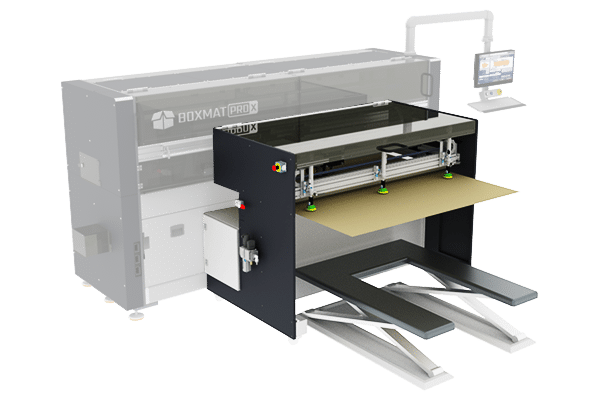

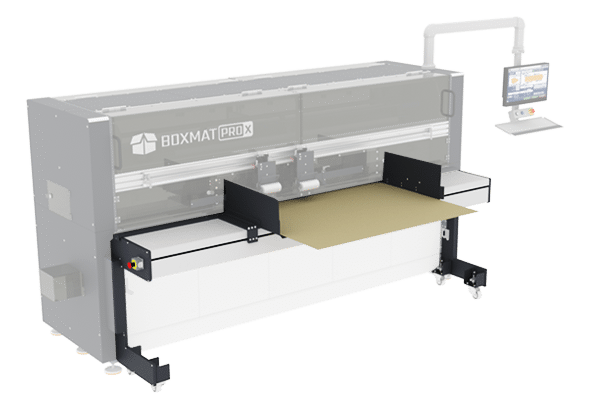

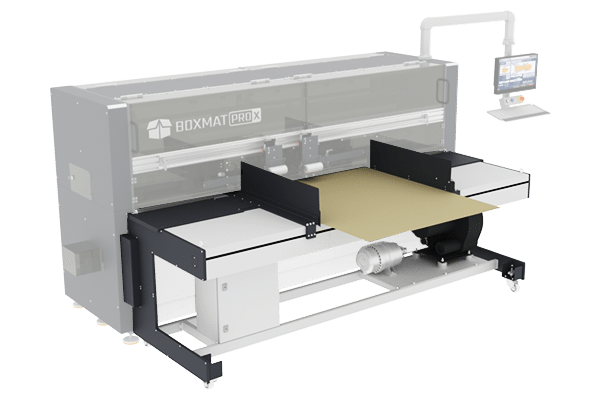

One of the key advantages of the Boxmat PRO X is its ability to work with a variety of feeders and input systems – a major upgrade from the previous generation. The machine supports:

- Standard Feeder (STD)

- Vacuum Feeder (VF)

- Fanfold Feeder (FF)

- Lightweight Feeder (LWF)

- Heavyweight Feeder (HWF)

This flexibility allows for easy adjustment to different production workflows and cardboard formats. Whether you’re switching between fanfold and sheet stock or handling light or heavy corrugated board, Boxmat PRO X adapts to your setup – not the other way around.

Available feeders

Standard Feeder | STD

Vacuum Feeder | VF

Fanfold Feeder | FF

Optional features

Gluing System

Innovative cold gluing system for boxmakers gives a fresh and exceptional approach to the corrugated cardboard gluing cycle!

miniFLEXO System

Additional printing system for Boxmat machines. One color mini-flexo technology printing.

JETBOX 1600 Digital Printer

Digital printer allows printing on the outer surface of the box: text, barcodes numbers, symbols, images, BMC labels.

Features and benefits

- Adjustable double creasing rolls for heavy or multi-layer boards

- Circular or blade knives – depending on the application

- Slotting knives for precision box shaping

- Intuitive HMI with built-in Box Creation Wizard

- Conveyor waste/scrap removal system – for cleaner, uninterrupted operation

- Coroplast compatibility – allows production of corrugated plastic boxes

Technical Specification

Cardboard used: | Single and double wall B, C, BC + fanfold |

Types of boxes: | Preinstalled ~60 FEFCO styles + Box Wizard |

Power supply: | 3 x 380/415/480 V |

Minimum board size: | 250 x 650 mm (10 x 25″ ) |

Maximum board size: | 2400 x 1000 mm

(94 x 394″) |

Slot width: | 8 mm |

Sectional slotting knives: |

100 mm (4”) each |

Standard slotting knives length: | 500 mm (20”) each side |

Min./max. slotting knives length: | 200 – 700 mm (8 – 27 1/2”) |

Glue flap: | from 5 mm (3/16”) |

Footprint (L x W x H): | 3550 x 1650 x 1750 mm (142 x 65 x 69”) |

Weight: | 2500 kg |

Corrugated Box Maker Machine

– Consulting, Configuration, Ongoing Support

The Boxmat PRO X is a next-generation corrugated box maker machine designed for short and medium runs. As an upgraded version of the bestselling Boxmat PRO, it offers greater flexibility, faster setup, and compatibility with multiple feeders and handling systems. From fanfold to heavy-duty corrugated sheets, this machine adapts to your production workflow and growing packaging needs. At Zemat Technology Group, we provide end-to-end support for every corrugated box maker machine implementation – from selecting the right feeder to integrating optional modules like gluing or miniFLEXO printing. Our team helps configure machines tailored to your exact production goals, ensuring efficiency and scalability.

With remote diagnostics, fast-response service, and access to original parts, our technical support guarantees long-term value from every investment. Whether you’re launching in-house box production or expanding capacity, the Boxmat PRO X is a powerful corrugated box maker machine built for real-world performance.